Men's Regular Fit Denim Jeans Tech Pack Template

Tech Pack Template: Mens Regular Fit Denim Jeans Pant

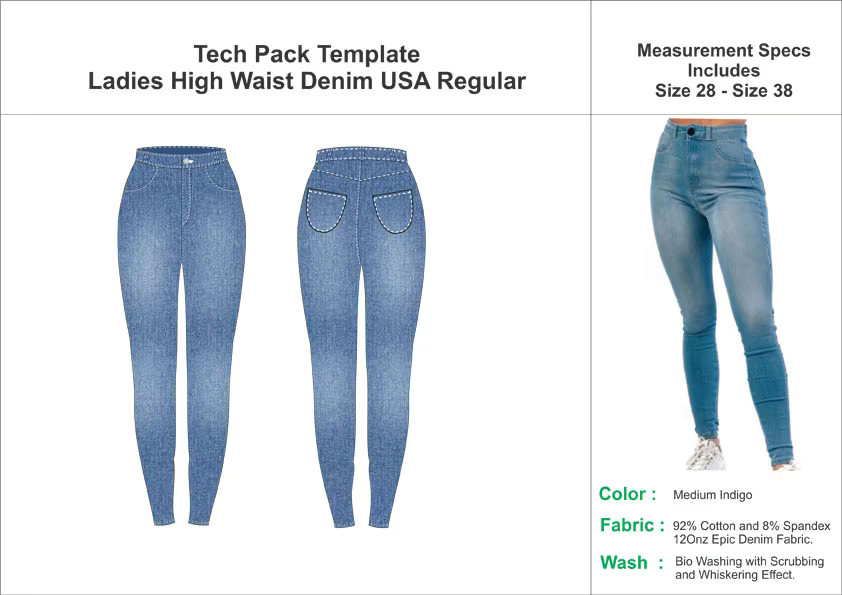

A tech pack is a comprehensive blueprint detailing fabric specs, measurements, trims, wash processes, and quality checkpoints for men’s regular fit denim jeans. With it, everyone—from the pattern maker to the laundry technician—understands exactly what to do. A precise tech pack reduces errors, cuts lead times, and ensures each pair lives up to both design intent and customer expectations.

1. What Is a Tech Pack and Why Is It Crucial for Men’s Regular Fit Denim Jeans Pant?

A tech pack is a detailed spec sheet capturing every design, material, measurement, and production instruction needed for men’s regular fit denim jeans. It aligns designers, manufacturers, and quality teams by eliminating guesswork—ensuring consistent fit, wash, and hardware details. Without it, miscommunication spikes, lead times balloon, and final products often stray far from the original vision.

1.1 Understanding the Tech Pack Concept

·Flat Sketches & Technical Drawings (front, back, side) with annotations

·Material Specs: denim weight, fiber composition, supplier codes

·Measurements & Grading Rules: exact waist, hip, thigh measurements per size

·Trim & Hardware Details: buttons, rivets, zippers, thread types

·Construction Notes: stitch types, seam allowances, pocket bag fabrics

·Wash & Finish Instructions: enzyme or stone wash details, resin coatings

·Labels & Packaging: main labels, leather patch dimensions, polybag specs

·Bill of Materials (BOM): itemized list of fabrics and trims with supplier info

·Quality Control (QC) Checkpoints: tolerance ranges, testing methods, sustainability checks

1.2 Why Regular Fit Demands Extra Precision

·Fit Consistency: A 1 cm difference in the thigh can make your size 32 feel more like a size 30 or 34.

·Brand Reputation: Customers expect the same feel every time they reorder. If last season’s 32 felt perfect but this season’s suddenly feels tight, you risk lost trust.

·Cost Efficiency: Without exact specs, factories do reworks. Reworks mean more labor cost, wasted fabric, and delayed shipments.

2. Which Key Sections Should Be Included in a Denim Jeans Tech Pack Template?

A tech pack template should cover flat sketches, material specs, measurements and grading rules, trims and hardware, construction notes, wash instructions, labels and packaging, BOM, and QC checkpoints. Using a “tech pack template mens regular fit denim jeans pant” keeps all these organized and easy to follow.

Dive Deeper

2.1 Title Page & Revision Log

·Title Page: Clearly state Tech Pack Template: Mens Regular Fit Denim Jeans Pant plus brand name (e.g., DiZNEW), season, date, and version number (V1, V2).

·Revision Log: Track changes—date, description, who approved. Example:

| Version | Date | Changes | Approved By |

| V1 | 2025-06-01 | Initial draft | Designer A |

| V2 | 2025-06-04 | Updated waistband height from 26 cm to 27 cm | QA Team |

| V3 | 2025-06-07 | Added sustainability criteria section | Sustainability Manager |

2.2 Flat Sketches & Technical Drawings

·Front View: Show pocket openings, fly type (zipper or button), waistband height, front yoke angle.

·Back View: Illustrate back pockets (shape, dimension), seat darts (if any), waistband extension, leather patch location.

·Side View: Highlight side seam structure, leg taper angle, coin pocket angle.

3.How Do You Specify Fabric, Wash, and Material Details for Regular Fit Jeans?

Detail denim weight (e.g., 12 oz slub), fiber composition (98% cotton, 2% elastane), and finish specifics (sanforized: ≤1.5% shrinkage). Document wash processes—enzyme or stone wash parameters, distressing techniques, and resin coatings—to ensure each pair matches the intended look and feel.

Dive Deeper

3.1 Fabric Specifications: It’s More Than “Just Denim”

·Denim Weight & Construction:

·12 oz Slub Selvedge vs. 14 oz Cone Mills: You might think “12 oz is 12 oz,” but slub denim often has thicker yarns and a looser weave, giving a textured hand. By contrast, a 14 oz Cone Mills denim is denser and more rigid. Document “12 oz S-Type Slub Selvedge, 98% cotton ring-spun, 2% elastane” to avoid confusion.

·Weave Pattern: Right-hand twill vs. left-hand twill matters—right-hand usually fades differently. Include "RH Twill, 3/1 weave."

·Dye Method: Indigo rope dye vs. slasher dye. Rope-dyed yarns create richer, longer-lasting fade patterns. Specify “Rope-dyed 8 times with indigo, followed by resin wash.”

·Fiber Composition & Stretch:

·Elastane Content: 1% elastane gives slight give; 2% makes a comfortable stretch; 3% provides more recovery but can weaken vintage hand feel. If comfort is key, specify “2% elastane—balanced stretch.”

·Recycled Yarn Blends: To hit sustainability targets, you might do “30% recycled cotton blended with 70% virgin cotton.” Spell out “Recycled content certified by GRS (Global Recycle Standard).”

3.2 Wash & Finish Documentation: Balancing Art and Science

①Enzyme Wash:

·Enzyme Type & Brand: Include exact enzyme (e.g., “Cellulase Enzyme, Brand X, Lot #5567”).

·Parameters: Concentration 1.5%, 45 minutes at 40 °C, pH adjusted to 6.5. Document “Pre-soak for 10 minutes, then enzyme wash.”

·Desired Outcome: Mid-blue shade with soft hand feel—label “Target Shade: Pantone 19-3921 TCX (Blue Iris).”

②Stone Wash:

·Stone Type & Size: “Pumice #30–60, locally sourced, washed and dried before use.”

·Ratio & Duration: 1:4 ratio, 30 minutes at 25 RPM.

·Result: Vintage worn look with subtle fading—document “Aim for 20% color loss in thigh area.” Use spectrophotometer to measure L* value (target L* = 32–34).

③Distressing & Laser Finishing:

·Manual Distressing: Sanding with grit 150 sandpaper—document “Apply 10 passes at 45° angle on whisker areas.”

·Laser Etching: “Laser Settings—Power: 50%, Speed: 200 mm/s, Frequency: 10 kHz.” Laser engraves whisker patterns with consistent precision.

④Resin & Softener Coating:

·Resin: “Resin Brand Z, 0.5% by weight, applied via padder at 20 m/min, dried at 60 °C.” Results in a crisp finish.

·Fabric Softener: “Softener Brand Y, 0.3% by weight, 3-minute final rinse, tumble dry on low.” Achieves a supple hand.

4. How Are Fit Measurements, Grading Rules, and Tolerance Guidelines Defined?

List core measurements (waist, hip, thigh, knee, inseam) in precise units, along with grading increments (+5 cm waist per size) and tolerance ranges (±0.5 cm). Accurate specs ensure each size of regular fit denim holds true to intended body dimensions.

Dive Deeper

4.1 Breaking Down Core Measurements

For men's regular fit denim jeans, these points are non-negotiable:

·Waist (measured at waistband)

·Hip (9 cm below waistband)

·Thigh (2 cm below crotch seam)

·Knee (midpoint between crotch and hem)

·Leg Opening (hem circumference)

·Inseam (from crotch seam to bottom hem)

·Front Rise & Back Rise (crotch edge to top of waistband)

4.2 Grading Increments: Scaling Sizes Smoothly

Grading rules help you scale up (or down) from a base size (typically size 32). Common increments for men's regular fit denim:

·Waist & Hip: +5 cm per size

·Thigh & Knee: +2 cm per size

·Leg Opening: +1.5 cm per size

·Front & Back Rise: +1 cm per size

·Inseam: Typically fixed (81.5 cm), but can vary by Short/Regular/Long

5. What Technical Drawings, Flat Sketches, and Specs Are Necessary for Clarity?

Include clear front, back, and side flat sketches annotated with seam lines, pocket placement, belt loops, and label positioning. Add detail insets for complex areas—like coin pocket stitch patterns and yoke angles—so manufacturers know exactly what to build.

Essential Views and Angles

①Front View:

·Shows pocket openings, fly closure (zipper or button), waistband height relative to crotch, front yoke angle (e.g., 20°).

·Annotate belt loops: “5 belt loops, each 2 cm wide, spaced 3.5 cm apart, starting 5 cm from side seam.”

②Back View:

·Illustrates back pockets (dimensions, position), seat darts or lack thereof, leather patch location (centered 5 cm above back yoke seam).

·Label “Back Pocket Topstitch Pattern: Double line, 0.5 cm from edge.”

③Side View:

·Depicts side seam construction (flat-felled vs. overlocked), leg taper angle (e.g., 5° taper from knee to hem), and coin pocket orientation.

·Include “Coin Pocket Angle: 15° tilt toward side seam.”

6. How Are Quality Control Checks, Testing Standards, and Sustainability Requirements Integrated?

Quality control outlines checkpoints—fabric inspection, in-line seam checks, post-wash colorfastness tests, and final inspection. Testing standards (AATCC, ASTM) ensure durability, while sustainability metrics (water usage targets, Oeko-Tex certification) embed eco-friendly practices throughout production.

Dive Deeper

6.1 Quality Control (QC) Checkpoints Throughout Production

①Pre-Production Fabric Inspection

·Check for Defects: Inspect every roll for slubs, thins, or holes. Maximum allowed: 5 flaws per 100 meters.

·Color Consistency: Compare indigo shade to approved standard (D65 lighting), record Delta E (target ≤2).

②In-Line Production Checkpoints

·Sewing QC: Sample every 50 garments: test seam strength (ASTM D1683, target ≥10 N/cm), stitch density (12–14 stitches/inch), seam alignment (pocket to side seam alignment within ±0.5 cm).

·Hardware QC: Verify buttons and rivets—no loose hardware. Use torque tester (target ≥15 N·mm).

③Post-Wash & Finishing QC

·Shrinkage Test: Measure length and width after wash; shrinkage must be ≤1.5% (AATCC 135).

·Colorfastness to Washing: AATCC 61-2A, no more than grade 3 staining on a white adjacent fabric.

·Colorfastness to Crocking: AATCC 8—target no more than grade 4 color transfer (wet and dry).

④Final Inspection

·Appearance & Hand Feel: Check for unintended abrasions, uneven fades, and softness.

·Fit Sample Verification: Randomly pick sizes 30, 34, 38—confirm measurements match tech pack within tolerances.

·Packaging QC: Verify each jean is folded correctly, tags are attached, and the polybag label matches size and style.

6.2 Social Compliance & Traceability

·Supplier Code of Conduct: Require all trim suppliers to sign DiZNEW's Code of Conduct—no child labor, fair wages, safe working conditions.

·Fabric Traceability: Source denim from mills that publish “Chain of Custody” certifications—e.g., Better Cotton Initiative (BCI). Document “Denim sourced from ABC Mills, BCI-certified for 2024 crop.”

·Audit Frequency & Reports: Mandate bi-annual environmental audits with public summary reports—post links in tech pack for transparency.

Conclusion

At DiZNEW, our Tech Pack Template: Mens Regular Fit Denim Jeans Pant ensures precision and consistency—whether you order 30 pairs for a special drop or 3,000 for a new collection. We integrate sustainability at every step: enzyme wash cycles consuming ≤30 liters per garment, Oeko-Tex 100-certified fabrics, and closed-loop water systems. Our in-house R&D team collaborates with top mills to source the best slub selvedge denim, achieving that perfect balance of comfort, durability, and fadeability.

Let's bring your denim vision to life—without compromise. Contact DiZNEW now to request your custom tech pack. Whether you need an editable PDF template or a fully branded spec sheet optimized for production, our team is ready to collaborate. Drop us a line, and let’s create jeans that fit like a dream, feel like a second skin, and showcase your brand’s story—one stitch at a time.