Professional explanation of jeans washing process

From basic to advanced, a comprehensive analysis of the essence and innovation of jeans washing technology

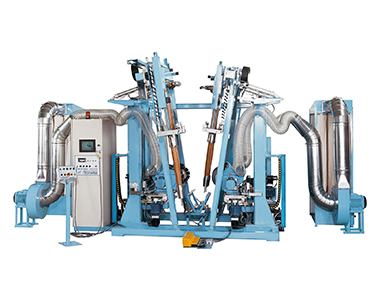

Garment Washing Factory

We formally invested in a self-built washing plant in 2025, which is equipped with advanced equipments to support a variety of processes such as enzyme washing, sandblasting, cat whisker, stone washing and so on. The self-built washing line makes us more efficient and controllable from production to shipment, guarantees the quality of garments, shortens the delivery time, and supports customers' rapid sampling and bulk orders. Welcome to visit our factory or come to us for customization!Learn More

1. Introduce

As a classic and timeless clothing category, jeans derive much of their unique appeal from the washing process. The washing process not only gives jeans a unique appearance effect, but also enhances their comfort and wearing experience. For factories specializing in high-quality jeans, comprehensive knowledge and skills in the wash process are key to building long-term relationships with American designers, growing and established brands.

This article will cover all aspects of jeans washing process, from historical evolution, basic knowledge, process details, sustainable washing solutions to future trends. Whether you are an industry professional, designer, brand owner, or a hobbyist interested in jeans washing process, you can get valuable information and insights from it.

2. A Brief History Of Washing Technology

Every wrinkle and faded spot on jeans wasn’t always just time’s doing. Originally, workers wore out the personality of their jeans through use; now, industrial washing makes this "aged" look a quick-to-replicate aesthetic. From stone washing to laser aging, jeans have become a battleground of fashion, efficiency, and environmental concerns.

3. Basic knowledge of jeans fabric and dyeing

3.1 Main types and characteristics of denim fabrics

- Classification by weight

Denim fabrics are usually classified by weight (ounces) per square yard, ranging from lightweight (5-9 ounces) to super heavyweight (over 17 ounces). Different weights have different washing effects and applicable processes. - Classification by weaving method

Denim with different weaving methods, including right twill, left twill, broken twill and plain weave, affects the appearance, feel and effect of the fabric after washing. - Classification by raw material composition

From traditional 100% cotton, to stretch denim with added elastic fibers, to various blended and recycled denim, fabrics with different compositions have different washing characteristics. - Classification by dyeing method

Denim with different dyeing methods such as warp dyeing, full dyeing and yarn-dyed will show different color fading effects and visual characteristics during the washing process.

3.2 Indigo Dyeing Process And Principle

Indigo dyeing is the core process of denim production. It not only determines the initial color of denim, but also directly affects the subsequent washing effect. Understanding the process and principle of indigo dyeing will help to have a deeper understanding of the chemical changes and visual effects of jeans during the washing process.

1. Reduction

First, the water-insoluble indigo dye is reduced to soluble white indigo by a reducing agent (such as sodium dithionite, glucose, etc.) in an alkaline environment.

4. Repeating

Since only a small amount of dye can be attached to the fiber each time, it is necessary to repeat the dyeing-oxidation cycle many times to achieve a dark effect.

Among them, these three are included

Rope Dyeing, Sheet Dyeing, Continuous Dyeing

2.Dyeing

The yarn is immersed in a dye solution containing white indigo, and the white indigo molecules penetrate into the fiber surface.

3.Oxidation

The dyed yarn is exposed to air, and the white indigo quickly oxidizes back to water-insoluble indigo and fixes on the fiber surface.

4. Detailed Explanation Of Basic Washing Process

The basic washing process of jeans is a key link to ensure wearing comfort and consistency of product appearance. They not only improve the texture of the fabric, but also lay the foundation for subsequent advanced processes.

4.1 Garment Wash:

Remove slurry impurities and improve softness. Water temperature 60°–90°C, time 5–30 minutes, add detergent and softener. The effect is soft, the color is slightly lighter, and there is no obvious sense of aging. Suitable for dark raw denim or pre-treatment of subsequent processes.

4.2 Stone Wash:

Create natural fading and wear through pumice friction. Use yellow stone, white stone, etc., 30–90 minutes of low water level treatment, and the amount of pumice is 30%-50% of the weight of the clothes. The effect is uneven whitening of the fabric surface, showing a retro and old feeling. Suitable for retro jeans.

4.3 Enzyme Wash:

Use cellulase at 40°–60°C, pH4.5–5.5 for 30–60 minutes to produce soft, evenly faded and peach skin feeling. Suitable for high-end, comfortable jeans.

4.4 Sand Wash:

Add sand wash agent and polygonal/round sand powder, and process at 40°–60°C for 30–60 minutes to enhance the softness and frosty fading of the fabric. Suitable for daily casual style jeans.

4.5 Bleach Wash:

Use chlorine bleach (NaClO) or oxygen bleach (H₂O₂) for 7–10 minutes. Chlorine bleach is rough, while oxygen bleach is more uniform. It shows a significant lightening effect, suitable for design styles that emphasize color contrast.

5. Pro Wash Tech

- 5.1 Whisker Effect:

Simulates wrinkles and color fading when worn. Common forms include:

·Ordinary whiskers:hand-rubbed process, low cost, suitable for fast fashion;

·3D whiskers:light and dark layering, high technical requirements, seen in high-end brands;

·Hand-sewn whiskers:natural texture formed by seams or hot pressing, visual three-dimensional, relatively unique;

·Laser whiskers:precise grinding through laser, high efficiency and good environmental protection, suitable for large-scale production but slightly lacking in naturalness.

- 5.2 Snow Wash

In snow wash, pumice stones are soaked in a potassium permanganate solution and used to dry-grind denim, creating a random white speckled pattern known as the "snowflake" effect. Afterward, oxalic acid is used to neutralize the chemicals. This technique offers strong visual contrast and artistic flair, making it popular for vintage-inspired jeans that stand out with unique and bold expressions.

- 5.3 Chemical Wash:

A chemical wash uses strong alkaline additives such as sodium hydroxide (NaOH) and sodium metasilicate (NaSiO₃), typically applied at 60°–80°C for 30–60 minutes. This process produces a noticeable faded appearance with a soft, fuller hand feel. When combined with stones (stone-chemical wash), it enhances the distressed, vintage look. Ideal for denim styles that emphasize worn-in character and softness.

6. Sustainable Denim Washing Solutions

- 01

Ozone Wash

Use ozone gas to fade denim, almost no water and chemicals are used, suitable for creating natural old and vintage effects.

- 02

Laser Distressing

Use laser to form cat whiskers, frayed and other patterns on the fabric, completely dry treatment, no need for water washing and chemicals, is one of the most environmentally friendly old-fashioned technologies at present.

- 03

Bubble Wash

By injecting nano bubbles into the water, the washing effect is enhanced, the water consumption and detergent usage are reduced, and the washing efficiency is improved.

- 04

Eco Stone Wash

Use ceramic balls or resin balls instead of traditional pumice stones to reduce stone powder pollution. The balls can be reused, and the washing consistency and environmental protection are improved.

- 05

Waterless Bleaching

Use dry technology to deal with the color change of denim, without using water resources, suitable for light-colored aging process.

- 06

Water Recycling System

Equipped with a closed-loop water treatment system, it ensures that wastewater is effectively purified and recycled throughout the production process. This not only reduces fresh water consumption and operating costs, but also significantly reduces emissions.

- 07

Eco-friendly Chemicals

We use biodegradable detergents, oxidants and softeners, such as hydrogen peroxide instead of bleach, to reduce the impact on the environment and workers' health.

- 08

8. Energy Efficiency

Use low-temperature washing water systems, high-efficiency equipment, heat recovery systems, and solar-assisted equipment to reduce carbon footprint.

7. Conclusion

7.1 The Art and Science of Denim Washing

Denim washing is a unique blend of art and science. On the artistic side, it reflects the creativity and aesthetic vision of designers and technicians, expressing different styles through diverse wash effects. On the scientific side, it relies on expertise in textile engineering, chemistry, and machinery, requiring precise control of parameters and strict quality management.This combination of creativity and technology is what makes denim washing both highly technical and deeply expressive. A well-washed pair of jeans is not just apparel—it’s a work of art and a product of advanced craftsmanship.

7.2 Future Outlook & Industry Direction

Looking ahead, the denim washing industry is evolving in the following key directions:

1. Sustainability

Eco-friendly washing technologies will become the industry standard. Water recycling systems, green chemical alternatives, and energy-efficient equipment will continue to drive innovation—fueled by growing consumer demand for sustainable products.

2. Digitalization & Smart Technology

Technologies like 3D design, digital sampling, and automated process control will enhance accuracy, efficiency, and creativity. AI and data analysis will also play a key role in optimizing washing parameters and quality control.

3. Customization & Personalization

As consumers increasingly seek unique styles, denim washing processes will shift toward small-batch, diverse, and flexible production. Customized wash finishes will become a key differentiator for brands.

4. Globalization & Localization

While denim production continues to expand globally, more attention is being paid to local styles and cultural influences. Regional techniques and aesthetics are blending to create a richer, more diverse denim culture.

Work with us to create high-quality jeans

We are a factory specializing in the production of high-quality jeans, with rich experience in washing technology and advanced production equipment. Whether you are an American designer, a growing brand or a mature brand, we can provide you with professional jeans production solutions.

Frequently Asked Questions

Please see below for frequently asked questions, if you have other questions, please contact us directly, we will answer for you at any time.

- What do I need to prepare to start?To start your order with DiZNEW, your trusted jeans manufacturer, please prepare the following materials:

1.Branding Files:

Your logos in vector file formats such as .AI, .PSD, .EPS, .SVG, or .PDF.2.Designs:

Tech packs detailing your designs. If you don’t have tech packs, you can provide at least three high-resolution reference images from different views or sketches. Alternatively, share your design inspirations with us, and we can provide free mock up for your confirmation.3.Artwork Files:

Files for print, embroidery, notions, and packaging must be in vector file format with dimensions specified. We can also offer guidance on appropriate sizes if needed.4.Sizing Information:

A size chart with garment measurements for each design. You may also choose from our size options, as we have selections available from famous brands. Please note that body measurements cannot be used.Having these materials ready will help ensure a smooth and efficient production process. If you have any questions or need assistance with your preparations, feel free to contact our team. - What's the MOQ for your jeans manufacturing?The minimum order quantity (MOQ) for jeans manufacturing at DiZNEW starts from 30 pieces across all designs for each order. Please note that for custom hardware, fabrics, trims, notions, dyeing, printing, embroidery, bags, and leather patches, different MOQs may apply.For specific details regarding MOQs for custom items or to discuss your order requirements, please kindly inquire with our team, and we will be happy to assist you.

- How long will it take to receive a response regarding a quote or other inquiries?At DiZNEW, we prioritize timely communication with our clients. You can expect to receive a response regarding your quote or other inquiries typically within 10 hours. Our dedicated customer service team is committed to addressing your questions and providing the information you need to move forward with your order.If you have urgent inquiries, please feel free to indicate the urgency in your message, and we will do our best to accommodate your request. Thank you for choosing DiZNEW as your trusted jeans manufacturer.

- Can I order a sample before ordering?

"Yes, you can order a sample before placing a production order. Pre-production samples are created exactly as they will be in large-scale production to ensure all details are confirmed. We require payment for the sample and shipping costs. However, if you place a direct production order, we can accept a deposit instead of the sample fee, though you will still need to cover the shipping costs for the sample. This process ensures you are satisfied with the design and quality before committing to a larger order.

We offer both prototyping and sample production services to meet your needs. Our prototyping service allows you to see and feel the exact product, ensuring every detail meets your specifications. This way, you can be confident in the final production run. Please note that while we cover the production costs for direct orders, sample shipping costs are the responsibility of the customer. This approach ensures transparency and trust, providing you with the highest level of service and quality." - Payment & Business Terms

Q30 What payment methods do you accept?

A: We accept T/T (bank transfer) and L/c for larger orders. All payment channels are secure and traceable.Q31 What are your standard payment terms?

A: for new clients, we typically require a 40% deposit to begin production, with the balance payable before shipment.Q32 Can the deposit ratio be adjusted forlong-term cooperative clients?

A:Yes,for our valued long-term patners, we can fexibly adjust the deposit ratio based on order volume, cooperation history, and credit evaluation.Q33 Can lpay in different currencies (USD, EUR, etc.)?

A: Yes. We support payments in USD, EUR, AUD, and more to accommodate international clients.Q34 What is your refund or cancellation policy?

A: Once production begins, orders are non-refundable. For cancellations before production,fees may apply depending on the stage of development. - Do you work with startups or only established brands?Partnering with diverse businesses - from nimble startups and solopreneurs to established multinational corporations. Our tailored production solutions adapt seamlessly to your project scope and financial parameters, ensuring optimal ROI across all scales.

- How do I contact you?You can contact us anytime on whatsapp or by email at info@diznew.com.

- What payment methods are accepted?Payments:1.Wire Transfer From All Countries2.Pingpong Payment (Credit Card Accept)3.Alibaba Trade Assurance. Click for payment information.

- How Does DiZNEW Process Digital Printing on Denim?As a professional denim manufacturer, DiZNEW employs advanced digital printing technology through a systematic process:

Key Production Steps:

1.Pre-treatment

Professional fabric preparationSurface treatment for optimal ink absorption2.Digital Printing

High-precision printing equipmentWater-based eco-friendly inksDirect design application3.Heat Setting

Professional heat curingColor fixation processDurability enhancement4.Quality Assurance

Print quality verificationWash test confirmationColor consistency check - Can Embroidery Be Done on the Printed Part of the Jeans?Yes, DiZNEW can apply embroidery on printed areas of jeans, but specific technical considerations apply:

Technical Considerations:

Print type must be assessed for embroidery compatibilityDesign placement requires professional planningSequence: printing is completed before embroideryQuality control measures ensure durabilityRecommendations: We recommend consulting with our technical team during the design phase for optimal results. - What Inks Do We Use for Digital and DTG Printing on Denim?DiZNEW uses premium water-based inks for both digital and DTG printing, specifically engineered for denim applications. These inks deliver:Superior color vibrancy on denimExcellent wash durabilitySoft hand feelEco-friendly printing results

- What Inks Do We Use for Screen Printing on Denim?As a professional denim manufacturer, DiZNEW uses specialized inks tailored to different denim washes:Light Denim: Water-based inks for breathable, soft-touch finishDark Denim: Plastisol inks for maximum color vibrancy and durabilityOur ink selection ensures optimal print quality and wash resistance for all denim products.

- What Printing Method Do You Use for All-Over Prints?Our printing methods are specifically selected based on fabric type to ensure optimal results:

Fabric-Specific Solutions:

Cotton & Cotton-Poly Blends: Digital or screen printingRayon/Tencel/Modal: Digital printingPolyester: Sublimation printingLearn more about our printing expertise - Do You Use a White Under Base for Printing?Screen printing: No white under base is used. Digital printing: Yes, white under base is applied for light-colored designs on dark fabrics to ensure color vibrancy.

Start cooperation

- Quick Quotation

- *Name

- Phone

Contact Person

- Name:

- Mohan

- Tel:

+86-0769-813126-86

- Email:

- info@diznew.com

- WhatsApp:

- 8613058567994

- Address:

- Fifth Ring Road No. 2 JiangNan Industrial West Area,ZhongTang,Dongguan,China

subscription