Where Are Lee Jeans Manufactured?

Denim is more than just fabric—it’s a cultural icon, a symbol of freedom, self-expression, and durability. From cowboys in the Wild West to today’s fashion runways, jeans have evolved, but one question consistently surfaces: Where are Lee jeans manufactured? Whether you’re a savvy shopper, a small-batch clothing brand, or a denim designer seeking insights, understanding the geography and dynamics behind Lee’s production can reshape your perspective on quality, ethics, and cost.

Lee jeans are produced in a multi-national network spanning the United States, Mexico, Bangladesh, Turkey, and China. Heritage or limited-edition collections often remain in the U.S., while core-volume lines are manufactured overseas for cost efficiency. All facilities must meet Lee’s stringent quality, environmental, and labor-practice standards, backed by certifications like Oeko-Tex, WRAP, and BSCI.

Imagine you’ve just sketched your dream denim design—raw selvedge with an artistic back pocket. You need a factory that balances craftsmanship, sustainability, and scalability. Let’s dive into how Lee built its global supply chain and how you, too, can leverage this knowledge to create your next denim masterpiece.

Why Do Consumers Ask “Where Are Lee Jeans Made?”

Consumers care about where Lee jeans are made because origin influences quality perception, ethical considerations, and price. “Made in USA” often signals premium craftsmanship, while “Made in China” or “Mexico” may suggest cost-effective production. Many shoppers look for transparency, sustainability credentials, and labor‐practice assurances before buying.

Perceived Quality and Heritage

When a brand like Lee touts “Made in USA,” it taps into a legacy of rugged craftsmanship that dates back to 1889. Consumers equate domestic production with tighter quality control, traditional techniques, and faster turnaround for special runs. However, reputable overseas facilities today can match or even surpass those standards—provided the brand enforces strict audits and ongoing training.

Ethical and Environmental Concerns

As awareness around fast fashion’s environmental toll grows, origin plays a critical role. Countries like Bangladesh and Turkey have made strides in wastewater treatment and chemical management, but issues remain. Shoppers increasingly demand third-party certifications (WRAP, BSCI, Sedex) to ensure fair wages, safe working conditions, and reduced environmental impact.

Price Sensitivity vs. Brand Loyalty

Domestic production often adds 10–25% to the cost of a pair of jeans—but some buyers willingly pay the premium for perceived authenticity. Meanwhile, cost-conscious consumers or emerging brands may prioritize MOQs (minimum order quantities) of 30–100 pairs and scalable pricing structures offered by factories in China and Mexico. For Lee, balancing heritage lines with mass-market offerings is key to retaining both segments.

Transparency and Traceability

Today’s shopper wants more than a label—they want a story. Where did that denim come from? What water treatment processes were used? How were workers treated? Brands that publish annual sustainability reports and maintain an open-book policy on their supply chain foster deeper customer trust.

Are Lee Jeans Still Made in the USA or Overseas Now?

Lee offers both U.S.-made and overseas-made jeans. Limited-edition heritage and high-premium lines are often crafted in the U.S., while core, high-volume products are produced in facilities across Mexico, Bangladesh, Turkey, and China. This hybrid approach balances brand heritage with competitive pricing for global markets.

U.S. Production: Heritage and Innovation

Lee’s headquarters in Greensboro, North Carolina, remains a hub for design, prototyping, and limited production. Special runs—like selvedge or raw denim—often stay stateside to ensure rigorous quality checks. These pieces boast:

• American-grown cotton options

• Traditional shuttle looms for authentic selvage edge

• Small-batch finishing with artisan wash techniques

However, U.S. facilities typically have higher operating costs and longer lead times, making them ideal for premium and collector’s items rather than mass-market offerings.

Mexico: Proximity and Flexibility

Mexico offers geographic proximity to Lee’s U.S. market, resulting in faster shipping times and reduced freight costs. NAFTA/USMCA agreements also lower duties on goods traded across the border. Mexican plants handle a significant portion of Lee’s mid-range jeans, leveraging:

• Skilled labor familiar with North American quality norms

• Efficient cut-and-sew lines that can pivot quickly for new styles

• Investments in water recycling and eco-finishing facilities

Bangladesh and Turkey: Cost-Effective Scaling

To meet global demand, Lee partners with high-capacity factories in Bangladesh and Turkey. These regions offer:

• Lower labor costs, enabling competitive pricing for volume orders

• Large-scale dye houses and wash labs capable of complex treatments (enzyme washes, ozone, laser distressing)

• Challenges: Brands must closely monitor for labor compliance, given historical industry concerns over worker safety and environmental management.

China: Technical Expertise and Customization

China remains a powerhouse for technical denim innovation—stretch technologies, performance finishes, and intricate embroidery. Factories there excel at:

• Advanced knitting and weaving for specialty denims (e.g., coated, waxed, or metallic finishes)

• Fast prototyping cycles, ideal for OEM/ODM clients who need small lots of complex designs (as low as 30 pairs)

• The caveat: Tariff fluctuations and rising labor costs have prompted some brands to diversify beyond China in recent years.

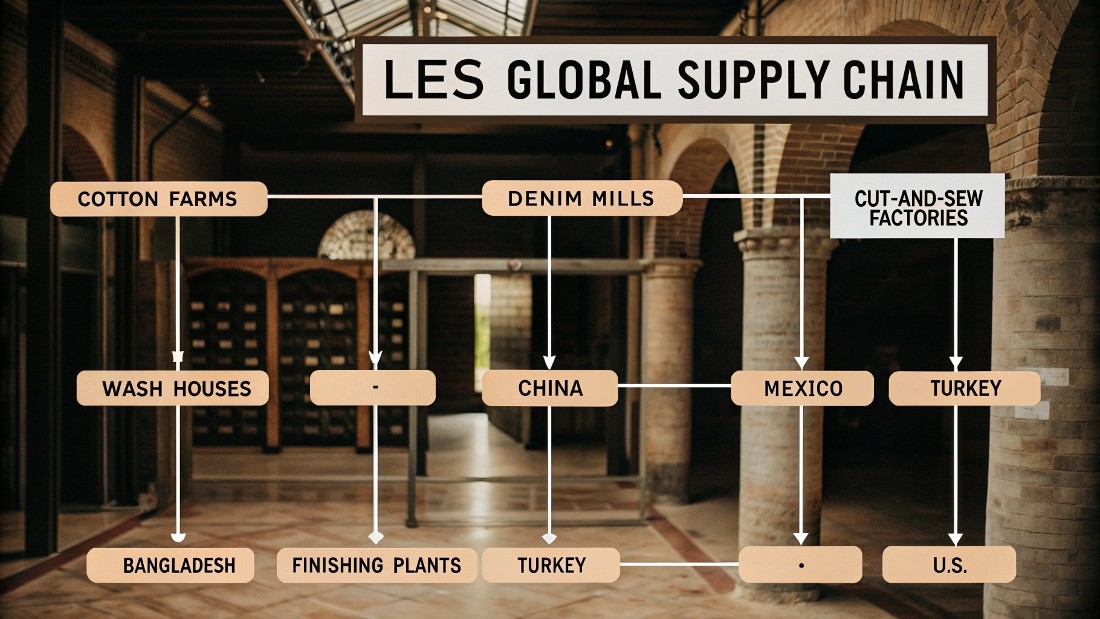

How Does Lee’s Global Supply Chain Operate?

Lee’s supply chain spans cotton farms, denim mills, cut-and-sew factories, and wash houses across multiple countries. Key denim mills are in China and Turkey, cut-and-sew hubs in Mexico and Bangladesh, and finishing plants in the U.S. and Turkey. Lee enforces consistent quality and ethical standards via third-party audits, real-time data tracking, and supplier training programs.

Raw Material Sourcing

Lee sources cotton from the U.S., Turkey, India, and Egypt. Each origin offers unique fiber qualities—U.S. Pima for long staple, Turkish cotton for balanced hand feel, and Indian cotton for cost efficiency. Strategic diversification mitigates climate risks and price volatility.

Denim Mill Operations

Major mills in China (Shandong, Jiangsu) and Turkey (Istanbul region) produce hundreds of denim variants—raw, sanforized, stretch, or ring-spun. Key investments include:

• Water-efficient dyeing machines (reducing water usage by up to 50%)

• Laser distressing units for eco-friendly abrasion

• In-house labs for color consistency and fast shade approvals

Cut-and-Sew Facilities

Mexico and Bangladesh handle 60–70% of Lee’s cut-and-sew volume. Lines are organized by fit families (slim, straight, relaxed) for efficiency. Real-time production dashboards monitor line speed, defect rates, and worker productivity—enabling quick corrective actions.

Wash and Finishing Houses

Wash houses in Turkey, China, and North Carolina apply techniques like enzyme washes, stone washes, and sandblasting alternatives. Many facilities have adopted closed-loop water systems and biodegradable chemicals, aligning with Lee’s sustainability targets.

Logistics and Distribution

Finished goods from Asia typically ship via container vessel to U.S. ports, then move by rail or truck to regional distribution centers. Mexican goods often use intermodal truck routes for rapid supply to U.S. retailers. Lee’s inventory management uses AI forecasting to optimize stock levels and reduce overproduction.

Quality and Compliance Monitoring

Lee mandates WRAP, BSCI, and ISO 9001 certifications. Quarterly audits, surprise inspections, and supplier scorecards ensure continuous improvement. Non-compliant partners undergo corrective action plans or face de-listing.

What Are the Quality and Ethical Standards Behind Lee Jeans Production?

Lee enforces rigorous quality and ethical standards through certifications like Oeko-Tex (harmful substance control), WRAP (ethical manufacturing), and BSCI (social compliance). Regular third-party audits, supplier training, and transparent reporting safeguard labor rights and environmental stewardship.

Oeko-Tex and Textile Safety

Oeko-Tex Standard 100 certification ensures that denim fabrics are free from harmful levels of chemicals and heavy metals. Lee requires all mills in its network to undergo annual Oeko-Tex testing, covering every product line from raw selvedge to stretch denim.

WRAP: Ensuring Ethical Production

WRAP (Worldwide Responsible Accredited Production) audits verify fair labor practices—no child labor, reasonable working hours, and safe facilities. Lee’s policy is zero tolerance: a factory losing WRAP status is immediately suspended from new orders until compliance is restored.

BSCI and Social Accountability

Through the Business Social Compliance Initiative (BSCI), Lee tracks metrics like hourly wages vs. local living wages, worker turnover rates, and grievance procedures. Factories below threshold scores must implement corrective action plans within 90 days or risk contract termination.

Environmental Management Systems

Many suppliers hold ISO 14001 certification for environmental management, demonstrating systematic efforts to reduce waste, control emissions, and optimize energy use. Specific targets include:

• 30% reduction in water usage per pair of jeans by 2025

• 40% decrease in greenhouse gas emissions relative to 2020 baseline

• Complete phase-out of hazardous chemicals by 2024, in line with Zero Discharge of Hazardous Chemicals (ZDHC) guidelines

Continuous Improvement and Supplier Engagement

Lee invests in supplier workshops on lean manufacturing, waste minimization, and social responsibility. High-performing partners receive preferred status, longer contract terms, and shared cost savings for joint sustainability projects.

How Can Small Brands Leverage DiZNEW’s Expertise to Compete with Lee?

DiZNEW offers customized denim manufacturing—plus sizes, baggy, stacked, skinny, jogger, and more—with low MOQs (30 pcs) and scalable volume runs (up to 10,000 pcs). U.S. designers and boutique owners can access China’s advanced mills and finishers to create unique, high-quality denim collections under their own brands (OEM/ODM), bridging the gap between artisanal craftsmanship and mass-market efficiency.

Versatile Fabric Sourcing

DiZNEW maintains partnerships with over 20 denim mills in Shandong and Jiangsu, offering a spectrum of fabric weights (8 oz to 16 oz) and constructions (ring-spun, slub, stretch). Clients can request specialized fibers—recycled cotton blends, Tencel for comfort, or nylon for durability—tailored to market trends.

Low MOQ, Fast Turnaround

Unlike large multinational brands requiring 1,000+ pairs per style, DiZNEW's minimum order is just 30 units, allowing emerging brands to test new fits and washes without huge inventory risk. Typical lead times:

• Sample to production-ready: 15–20 days

• Full batch (30–500 pcs): 30–45 days

• Bulk orders (1,000+ pcs): 60–75 days

Complex Styles, Precision Craftsmanship

From baggy and stacked silhouettes to tapered joggers and vintage selvedge, DiZNEW’s workshop houses specialized machines for:

• Coating, waxing, and distressing

• Laser and hand-finished abrasion

• Intricate embroidery and laser-engraved badges

• Hidden rivets, custom buttons, and pocketing details

OEM, ODM, and Branding Flexibility

Clients can:

• Provide their own design sketches or tech packs for strict adherence

• Choose from in-house designers to refine fits and specs

• Incorporate proprietary labels, hang tags, and packaging designs

• Benefit from end-to-end services from initial sampling to final QC inspections

Ethical and Quality Assurance

DiZNEW factories adhere to BSCI and WRAP standards, and fabrics meet Oeko-Tex criteria. Every production batch undergoes a four-stage quality check—fabric inspection, in-process line audits, wash verification, and final packaging review—ensuring consistency across runs.

Case Study Snapshot (Table):

Style

Fabric

MOQ

Lead Time

Order Size

Region

Skinny Selvedge

14 oz ring-spun

30

45 days

300

Shandong, China

Baggy Stretch

10 oz 2% elastane

50

35 days

1,200

Jiangsu, China

Vintage Washed

12 oz organic cotton

30

40 days

500

Hebei, China

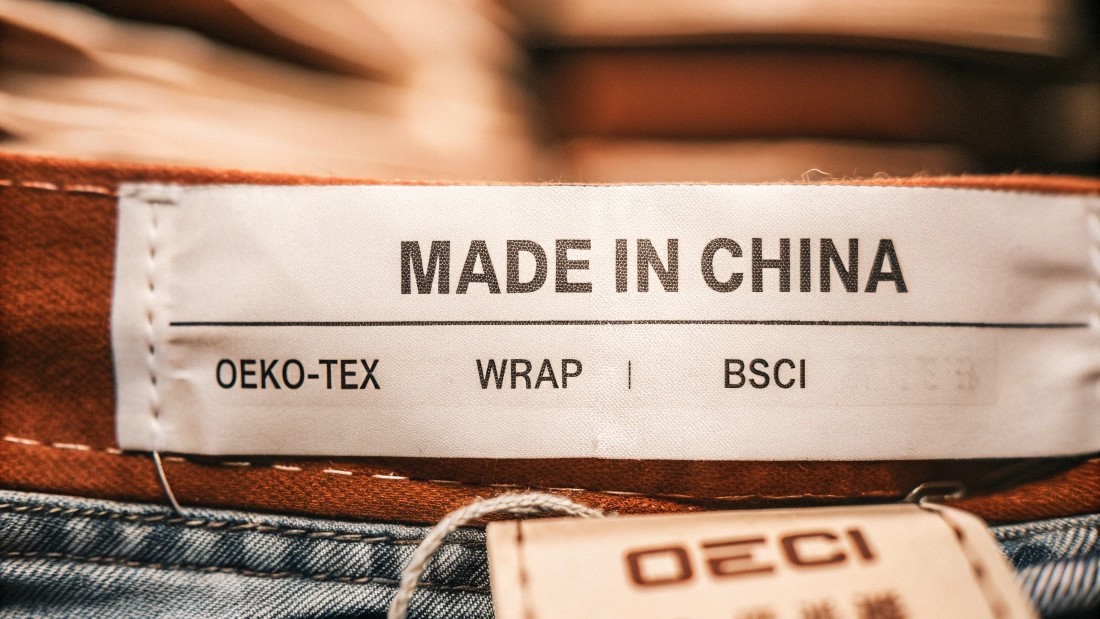

What Should Buyers Consider When Evaluating “Made In” Labels on Denim?

“Made in” labels on denim reflect production location, but not always quality. Buyers should assess fabric origin, factory certifications, and supply chain transparency. A “Made in China” tag can still deliver premium results if accompanied by Oeko-Tex, WRAP, and BSCI credentials. Look for brands that publish audit summaries and environmental impact data to make informed, ethical purchasing decisions.

Origin vs. Craftsmanship

The country on the label indicates where final assembly occurred, not where the cotton was grown or the denim woven. For example, a jean stamped “Made in Mexico” may use Turkish denim fabric and hardware from Italy, blending global expertise.

Certifications Over Borders

Rather than fixating on geography, prioritize:

• Oeko-Tex Standard 100 for chemical safety

• WRAP for ethical labor practices

• BSCI or Sedex for social compliance

These benchmarks provide objective measures of quality and ethics, irrespective of location.

Transparency and Traceability Tools

Brands that leverage blockchain or QR-code traceability empower consumers to scan and view:

• Farm of origin for cotton

• Mill processing data

• Factory audit results and worker welfare initiatives

Such transparency builds trust and combats greenwashing.

Environmental and Social Impact Metrics

Evaluate water usage (liters per jean), carbon footprint (kg CO2e per unit), and social investment (percentage of profits reinvested in worker programs). Leading brands publish annual sustainability reports with clear targets and progress updates.

Balancing Cost and Conscience

While “Made in Italy” or “USA” may command a price premium, smaller labels can achieve similar standards through strategic OEM partnerships (like DiZNEW) that maintain rigorous oversight without inflated markups.

Understanding where Lee jeans are manufactured reveals the intricate balance between heritage, quality, cost, and ethics in today’s global denim industry. As consumer expectations evolve—demanding transparency, sustainability, and unique design—small brands and boutique designers must adopt agile, value-driven manufacturing partners.

DiZNEW offers precisely that: a China-based factory with 20+ years of denim expertise, low MOQs, high customization capabilities, and uncompromising quality and compliance standards. Ready to bring your denim vision to life? Contact DiZNEW today for a free consultation on fabric selection, custom fits, and advanced finishes. Your next signature jean collection awaits—crafted to your exact specifications, delivered with integrity, and designed to impress.

Elegant dark denim jeans with pearl accents, perfect for boutiques and high-end custom fashion lines.

Vintage-washed wide-leg jeans with floral embossing, tailored for boutique brands and premium designers.

Make a bold statement in these wide-leg black jeans, detailed with shimmering rhinestone face art.

Black wide-leg jeans with sequin cross patches and distressed details – made for standout streetwear looks.