What Does “Custom Fit” in Trousers Mean? — Your Complete Guide for Denim Brands and Boutiques

Have you ever ordered a pair of trousers online only to find them mountains too loose in one area, painfully tight in another, or that weird diagonal twist down the leg? If so, you’ve experienced the frustration of off-the-rack sizing. “Custom fit” isn’t just industry jargon—it’s a promise that every key dimension and curve of your design, from waist to hem, is dialed in to match real bodies and real preferences. For denim designers, boutique owners, and direct-to-consumer brands, mastering custom fit can be the difference between a 30% return rate and a loyal customer base that can’t stop singing your praises.

Custom fit in trousers means adjusting the garment’s pattern, construction, and grading to align precisely with the measurements, posture, and style preferences of a target customer or brand. Unlike regular or modern fits, custom fit ensures consistent proportions across sizes, integrates fabric behavior (stretch, shrinkage), and undergoes iterative sample rounds—delivering fewer returns, higher customer satisfaction, and a strong brand identity.

Imagine a small US e-commerce boutique about to launch its first denim line. Their designer sends off “relaxed fit” sketches to a factory in China, only to get back samples where the rise is too low, pockets sag in odd places, and the thighs balloon out. Sales stall, returns climb. Then she partners with DiZNEW, a 20-year-veteran OEM/ODM in Jiangsu specializing in deep denim customization. Thirty samples later, every curve is right, every stitch purposeful—and the boutique sells out its first run. Stick around as we unpack exactly what goes on behind the scenes to make that happen.

What Is Custom Fit—and How Is It Different from Regular, Modern, and Tailored Fits?

Custom fit trousers use individualized measurements, pattern modifications, and grading rules to produce garments that match a specific body profile or brand aesthetic. Regular fit relies on generic size charts; modern fit tweaks those charts for current trends; tailored fit narrows and refines RTW blocks. Only custom fit—whether made-to-measure (MTM) or bespoke—delivers unique pattern drafting, multiple fit iterations, and brand-exclusive grading tables.

Definitions and Fit Categories

• Regular Fit (Ready-to-Wear): These trousers are built off a standard “block” or pattern based on industry-average measurements (e.g., 32" waist, 40" hip). Styles are labeled slim, straight, relaxed, or tapered. They’re fast to produce and cost-effective, but they assume an “average shape” that often doesn’t exist.

• Modern Fit: A marketing evolution of RTW. Brands shift curves, ease, or taper to cater to prevailing style trends (e.g., slimmer silhouette, mid-rise). The blocks are updated roughly every season, but still generic.

• Tailored Fit: Essentially a narrowed modern fit, often with slight adjustments for a cleaner seat or a raised rise. This is still RTW with limited personalization.

• Custom Fit: Encompasses made-to-measure (MTM) and bespoke. MTM starts with a base block, then adjusts 6–12 measurements—waist, hip, rise, thigh, knee, inseam—to create a unique pattern. Bespoke designs patterns from scratch: you take 20–30 measurements, postural analysis, optional 3D scans, and conduct multiple fittings. Grading (scaling the pattern across sizes) is also brand-specific.

Why Generic Blocks Fail

Bodies aren’t linear. For example, jumping from a size 30 to 32 waist might demand +1" in hip but +2" in seat. Generic grading applies the same increments across all dimensions, which leads to distortion and poor fit. Similarly, materials behave differently: a rigid 100% cotton twill needs more ease than a 98/2 stretch blend. Generic RTW doesn’t account for that.

The ROI of Custom Fit

Data from online denim retailers show that fit-related returns can be 20–40% of all bottoms returns. Implementing an MTM or bespoke program can cut that by up to one-third. Higher priced custom items also command better margins and stronger brand loyalty. One DiZNEW client reduced returns from 28% to 9% in six months after launching an MTM pilot.

Production Trade-Offs

• Lead Time: RTW can ship in 4–6 weeks, MTM takes 8–12 weeks, and bespoke 12–20 weeks.

• Cost: Bespoke > MTM > RTW. Bespoke often requires multiple fittings; MTM needs fewer rounds.

• Scalability: RTW is infinitely scalable; MTM scalable if you limit options; bespoke is labor-intensive and typically reserved for luxury.

By understanding these distinctions, brands can choose the level of customization that meets their quality, cost, and timeline goals.

How Do Manufacturers Achieve Custom Fit—Measurements, Pattern Making, and Grading?

Custom fit is created through accurate measurement capture (manual or 3D), block/pattern modifications (rise, crotch curve, seat shaping), prototype sampling, and brand-specific grading rules that preserve the fit across all sizes. Factories like DiZNEW provide iterative fit rounds, detailed tech packs, and post-wash measurement validation to ensure consistency and reduce returns.

Measurement Capture

• Manual Tape Measure: The most accessible method—waist, high waist, front/back rise, hip, thigh, knee, inseam, outseam, and hem. Staff must be trained to maintain consistent posture and tape tension.

• Self-Measure Kits: DTC brands ship rulers, instruction booklets, and photo guides to customers. Quality control depends on user compliance.

3D Body Scanning: Fast, repeatable, and captures posture, shoulder angles, pelvic tilt, and surface topology. Ideal for MTM at scale.

Pattern Block Modification

Once measurements are in hand, pattern makers adjust the basic block:

• Rise Adjustments: Front vs. back rise changes where the waistband sits and how the seat fits when sitting or bending.

• Crotch Curve: Crucial for comfort. A too-shallow curve restricts motion; too-deep creates sag.

• Seat/Back Shaping: Darts, curved seams, or additional panels eliminate gaping or bagging.

• Thigh/Knee Taper: Adjusted to match the intended silhouette—slim, straight, wide.

• Waistband Design: Contoured vs. flat band, extended tabs, elastic inserts to prevent gaping.

Prototype Rounds

Typically three to four rounds:

Muslin toile: basic shape verification, no fashion details.

Fabric-blend proto: checks drape and stretch (often uses an “approximate” fabric).

Final fit sample: in the exact production denim with trims, washes, and labels.

Each round includes measurement deviations (± mm), photos (front, side, back), and movement tests (sitting, squatting, walking).

Grading Across Sizes

After sign-off on a base size (e.g., 32 waist, medium), the pattern must scale up and down. RTW grading uses linear increments—e.g., +1” waist, +0.5” hip for each size. Custom grading defines unique increments for each measurement point so that a size 34 waist may need +1.2” hip and +0.7” thigh. DiZNEW maintains brand-specific grading tables to preserve the “fit DNA” across small, medium, large, plus, petite, and tall categories.

Post-Wash Validation

Denim typically shrinks 2–5% unless sanforized. A final set of measurements after wash and dry verifies that the end-user fit matches the spec sheet. This step is critical for unsanforized or garment-dyed denim.

Why Do Fabric and Construction Choices Matter for Custom Fit Trousers?

Fabric stretch, weight, recovery, and finish directly influence the ease required in a pattern, while construction details—waistband style, seam placement, pocket bags—alter how a garment drapes and moves. Custom fit development must integrate material performance data, prototype testing, and wash-test results to achieve the intended silhouette and comfort.

Fabric Behavior

• Stretch & Recovery: A denim with 2% elastane will need 1–1.5” more ease in the thigh than a 6% elastane fabric. Recovery dictates how much the garment bounces back after wear.

• Weight (GSM/Ounces): Heavier denim (12–16 oz) holds shape but can feel stiff; lighter (8–10 oz) drapes more and reveals every fit nuance.

• Shrinkage & Relaxation: Garment dye or unsanforized denim can shrink unpredictably. Patterns must compensate by pre-washing or adding extra ease.

• Hand & Finish: Coated or waxed denims sit differently than raw; enzyme or stone washes can soften and slightly distort dimensions.

Construction Details

• Waistband: A one-piece contoured waistband vs. two-piece can reduce gaping. Internal stays (twill tape) improve waistband stability.

• Seams & Topstitching: A curved side-seam can cinch the waist visually; a flat-felled inseam adds durability but changes stretch.

• Pockets: Deep or reinforced pocket bags add volume at the hip—impacting the side-profile silhouette.

• Fly: Button fly vs. zipper fly changes the front rise slightly and affects buttonhole placement.

• Reinforcements: Bar-tacks, rivets, and belt loop widths all add subtle bulk.

Prototype and Wash Testing

• Always do at least one fit sample in final fabric and finish. If the final fabric isn’t available, use a fabric with identical stretch, recovery, and weight data.

• Record fabric mill data: % stretch (weft/warp), recovery after 50% extension, GSM, washback % (shrinkage).

• Conduct wear-trial: Have fit models do daily activities—sit, squat, walk, cycle—and report pressure points or fit creep.

Integrating Findings into the Pattern

• If pockets cause bulges, reduce bag volume or reposition.

• If seat bags after wear, add seat darts or internal support seams.

• If the knee area drifts during walking, tweak the seam allowance or taper more aggressively.

By blending technical fabric science with construction artistry, custom fit becomes more than measurement—it’s a system that ensures each pair of jeans moves and looks exactly as intended.

Who Benefits from Custom Fit Trousers—and When Should You Choose It?

Custom fit trousers benefit designers, DTC brands, and boutiques aiming to reduce returns, boost brand loyalty, and serve niche body types (plus-size, athletic, petite, tall). End consumers with specific silhouette preferences or mobility needs also win. Consider custom fit when RTW return rates exceed 8–12%, when launching a premium line, or when targeting non-standard body shapes.

Designers & DTC Brands

• Brand Differentiation: A signature fit becomes part of your brand identity, letting you charge premium prices.

• Reduced Returns: Online retailers often see a 20–40% return rate on bottoms; MTM programs can cut that by 30%.

• Data Insights: Collecting customer measurements informs future design, improving size charts and marketing.

Retailers & Boutiques

• Niche Markets: Serve athletic builds (larger thigh, narrow waist), curvy silhouettes (higher hip-to-waist ratio), petite (shorter rise and inseam) or tall (longer inseam, higher rise).

• Personalization Services: Offer in-store measurement appointments or ship self-measure kits.

• Inventory Efficiency: By allocating small-batch MTM orders, you avoid dead stock of unpopular sizes.

End Consumers

• Comfort & Confidence: A well-fitted trouser enhances movement and posture.

• Personal Style: Options like stacked jeans, joggers, or selvedge with high-rise curvy cuts let buyers express themselves.

• Longevity: Proper fit reduces stress on seams and fabric, extending garment life.

When to Choose Custom Fit

• High Returns (>8–12%): Indicates fit mismatch in RTW.

• Premium Positioning: Customers expect custom or semi-custom services at higher price points.

• Small Initial Volume: MOQ 30 for fit sampling lets you test market demand affordably.

• Complex Styles: Baggy jeans with dropped crotch or stacked jeans need precise pattern engineering.

Use Cases & Data

Case Study: A boutique offering “athletic tapered” jeans (32 waist, 22" thigh) launched a 100-piece MTM run. Return rate dropped from 28% to 10%, and average order value rose 18%.

| Metric | RTW Line | MTM Pilot |

| Return Rate | 28% | 10% |

| AOV | $85 | $100 |

Customer Satisfaction | 3.8/5 | 4.6/5 |

| Repeat Purchase Rate | 12% | 25% |

Clearly, custom fit can transform both customer experience and the bottom line.

How Can You Partner with an OEM/ODM Like DiZNEW to Deliver Custom Fit Trousers?

DiZNEW offers end-to-end custom-fit trouser development: tech-pack refinement, low-MOQ fit sampling (30 pcs), iterative fit rounds, fabric R&D, bespoke grading, wash testing, and bulk production up to 10,000 units. Key steps include initial consultation, prototype approval, grading lock-in, and ongoing QC with measurement reports to ensure your brand’s fit DNA scales flawlessly.

DiZNEW’s Fit-Development Workflow

a) Initial Consultation: You share design sketches, target customer profiles, desired fabric types (rigid denim, stretch twill, selvedge), and order quantities (30–10,000). DiZNEW evaluates feasibility, suggests optimizations, and issues a preliminary quote.

b) Tech Pack & Spec Sheet Creation: DiZNEW refines your tech pack—adding detailed flat measurements, tolerances, material specs, trim lists, and construction notes. A robust spec sheet minimizes miscommunication.

c) Sample Rounds:

– Fit Sample 1 (MOQ 30): Muslin or fabric-blend toile to verify basic shape.

– Fit Sample 2 (MOQ 30): Proto in final fabric with trims and hardware.

– Pre-Production Sample (MOQ 30–100): Final fabric, wash, and labels—ready for photography and small-batch retail testing.

d) Fit Sign-Off & Grading: Once you approve the pre-production sample, grading tables are locked. DiZNEW generates brand-specific grading charts for all sizes (S–XXL, plus, petite, tall).

e) Bulk Production & QC: Production runs of 100–10,000 pieces commence. DiZNEW performs inline measurement checks, AQL inspections, and final wash tests. A detailed measurement report accompanies each shipment.

Key Questions to Ask Your Factory

• Measurements: Do you use 3D scanning, manual measures, or both? Can I supply my own fit model?

• Sample Costs & Lead Times: What’s included in the sample price? How many fit rounds?

• Fabric Sourcing: Do you source or will I ship fabric? What’s minimum yardage?

• Grading & Pattern Ownership: Who owns the patterns? Can I request the grading rules?

• Quality Assurance: What measurement tolerances do you guarantee? Are post-wash specs included?

• Certifications & Compliance: Can you share compliance certificates (e.g., ISO 9001, social audit reports)?

Scaling While Preserving Fit

DiZNEW’s strength lies in its dual capacity: small-batch flexibility and large-scale efficiency. Whether you need an initial 30-piece fit run or a 10,000-unit global launch, the same spec sheet, grading charts, and QC protocols apply—ensuring the trench from sample to truckload matches your original vision.

Real-World Example

A US lifestyle brand approached DiZNEW for a “curvy high-rise” selvedge jean. After two fit rounds with a fit model representing a 38W–50H ratio, they approved a sample. DiZNEW graded up to 5X and down to 00P (petite), produced 2,500 units, and delivered within 12 weeks. The client saw a 35% conversion lift and 22% fewer returns vs. their previous RTW supplier.

Cost & Timeline Overview (Indicative Table)

| Phase | MOQ | Lead Time | Cost Notes |

| Fit Sample Run | 30 pcs | 6–8 weeks | Includes 2 fit rounds; higher per-unit cost |

Pre-Production Sample | 30–100 | 8–10 weeks | Final fabric, wash, trims; for retail testing |

| Bulk Small Run | 1000 | 8–12 weeks | Grading locked; inline QC; post-wash measurements |

| Bulk Large Run | 10,000 | 12–16 weeks | Best per-unit price; full QA and packing options |

Choosing the right partner means more than low prices—it’s about technical expertise, honest communication, and the capacity to grow with your brand. DiZNEW ticks all those boxes.

If you’re a denim designer, boutique owner, or DTC brand ready to elevate your trouser fit from “good enough” to “perfect,” let’s talk. DiZNEW combines 20+ years of Chinese OEM/ODM denim mastery with a lean sampling structure (MOQ 30) and the capacity to scale to 10,000+ units. We handle everything: tech packs, fit iterations, fabric and wash R&D, grading, and stringent QC—so you can focus on marketing, sales, and delighting your customers.

Next Steps:

Gather your design sketches, target customer measurements, and fabric preferences.

Email contact@diznew.com or visit diznew.com/inquiry to request a sample quote and development timeline.

Share your tech pack or let us help you refine it with our in-house pattern experts.

Make returns a thing of the past and deliver trousers your customers rave about. Contact DiZNEW today to start your custom-fit denim journey.

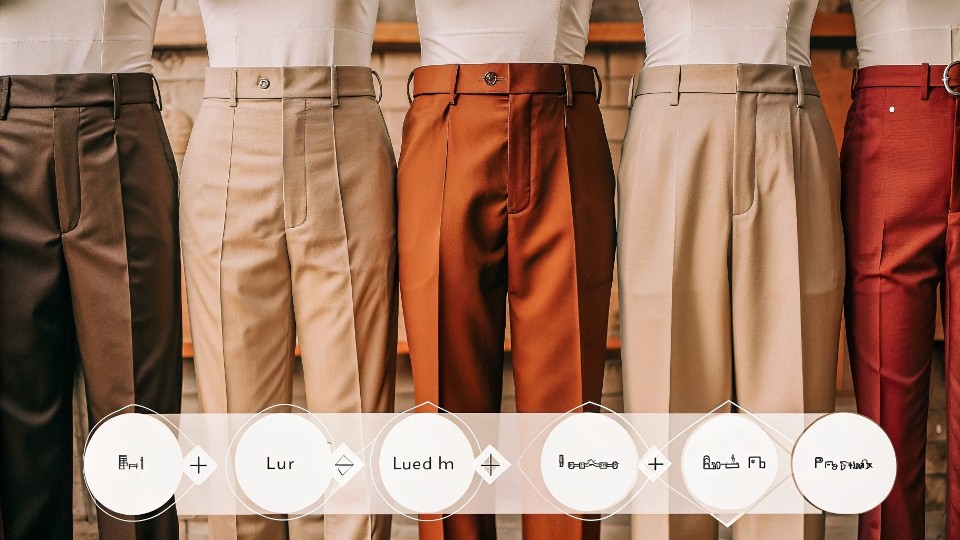

Statement camo trousers in soft earth tones—artful, relaxed, and made to stand out.

Tactical-inspired black shorts featuring camo underlayers, raw edges, and heavy distressing.

Bold custom denim shorts with graffiti art and patches — perfect for edgy boutiques and statement designers.

Heavily distressed custom denim shorts with edgy cuts—ideal for bold boutiques and luxury streetwear labels.