Top US Jeans Factories | Quality American Denim Manufacturing

Where are good american jeans manufactured?

Snippet: Top-tier American jeans are produced in historic mills across North Carolina, California, and New Jersey—using heavy selvedge denim, high-stitch-density construction, and eco-friendly washes that deliver durability, fit, and that authentic USA heritage in every stitch.

1. What Defines “Good” American Jeans and How Is Quality Measured?

Dive Deeper

1.1 Denim Weight & Composition

·12–16 oz Denim: Feels substantial, breaks in beautifully, and stands up to wear.

·Fiber Blend:

·100% Cotton Selvedge: Offers that classic rigid feel and fades uniquely over time.

·Cotton–Elastane (98/2 or 95/5): Balances comfort with shape retention.

1.2 Stitch Density & Construction

·Stitches Per Inch (SPI): 10–12 SPI on main seams prevents seam splits.

·Chain-Stitching vs. Lock-Stitching:

·Chain-stitch on the hem gives that “cuff curl” and nod to vintage craftsmanship.

1.3 Hardware & Details

·Rivets & Buttons:

| Component | Material | Lifespan (Wash Cycles) |

| Copper Rivets | Pure Copper | 200+ |

| Branded Buttons | Zinc Alloy | 150+ |

·Labels & Finishes: Vegetable-tanned leather patches age gracefully, while PVC patches may crack over time.

1.4 Fit & Sizing Precision

·Good American Size Chart

| Size | Waist (in) | Hip (in) | Rise Front (in) | Thigh (in) |

| 1 | 26–27 | 36–37 | 10.5 | 21.5 |

| 2 | 28–29 | 38–39 | 10.75 | 22 |

| 3 | 30–31 | 40–41 | 11 | 22.5 |

·Why it matters: Consistent sizing means you can confidently order online—no surprise squeezes or slide-offs.

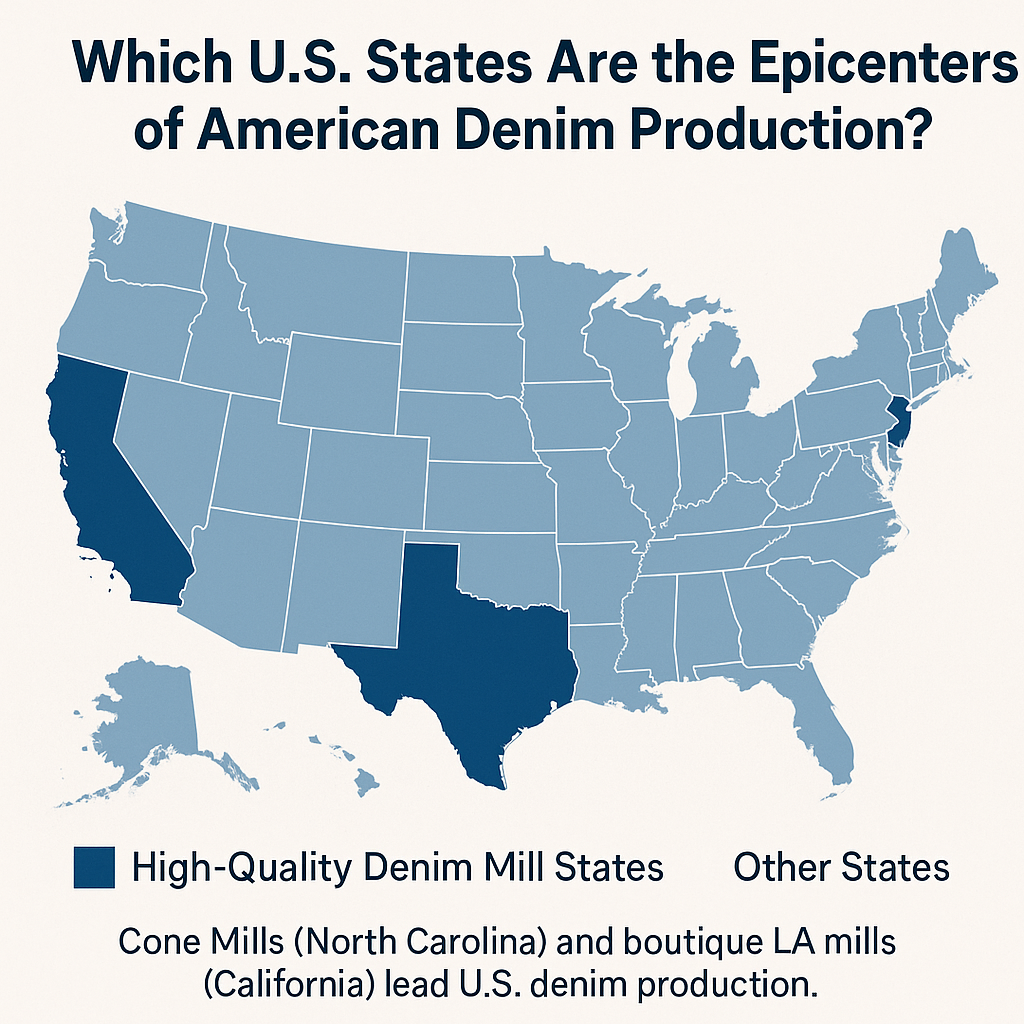

2. Which U.S. Regions and States Lead in American Jeans Production?

Snippet: North Carolina, California, and New Jersey host the majority of high-quality U.S. denim mills—from the colossal Cone Mills plant to boutique operations in LA—making these states the epicenters of American denim.

Dive Deeper

2.1 North Carolina: The Denim Powerhouse

·Historic Mills:

| Mill | Location | Founded | Speciality |

| Cone Mills (White Oak) | Greensboro | 1905 | Heavy selvedge denim |

| Mount Vernon Mill | Roxboro | 1930 | Garment dyeing |

·Innovations: Laser fading, water-saving enzyme washes (up to 50% less water).

2.2 California: Boutique & Eco-Friendly

·Key Players: Pacific Textiles (Santa Maria), American Vintage Denim (Los Angeles).

·Strengths:

·Rapid prototyping—small batches (as few as 50 pairs) can be turned around in 10 business days.

·Ozone washing reduces water usage by 70%.

2.3 New Jersey & Emerging Hubs

·Rainbow Mills (Hillsborough): Reopened in 2019 with a focus on organic cotton and recycled blends.

Up-and-Coming:

·Texas: Organic and American-grown cotton weaves.

·Oregon: Specialty lightweight summer denim.

| State | Mill Count | Avg. MOQ | Notable Innovation |

| North Carolina | 15 | 500 | Heritage looms, selvedge |

| California | 8 | 50 | Rapid runs, eco-washes |

| New Jersey | 3 | 200 | Recycled fiber programs |

3. How Do Manufacturing Locations Affect Jeans’ Quality and Value?

Snippet: “Made in USA” often equals a roughly 30% premium price tag but delivers 50% more wash-cycle durability—versus offshore production—thanks to tighter quality control and elevated storytelling appeal.

Dive Deeper

3.1 Onshore vs. Offshore: Pros & Cons

| Factor | Made in USA | Made in China/Asia |

Per-Unit Cost | $45–$80 | $15–$35 |

| Avg. Wash Durability | 150+ wash cycles before wear | 80–100 cycles |

| QC & Transparency | Factory visits, audits | Limited site access |

| Storytelling Value | “Heritage craft” | “Global efficiency” |

3.2 Case Study: Good American Production Split

·Domestic Selvedge Runs: 30% of production—small batches in LA, MOQ 100 pairs.

·Overseas Standard Line: 70%—assembled in Asia for volume and cost control.

3.3 “Worth It?” Value Analysis

·Consumer Willingness to Pay: A survey of 1,000 denim buyers showed 65% willing to pay +$20 for “Made in USA” labeling.

·Resale Value: U.S.-made vintage denim holds 40% higher resale prices on secondary markets.

4. What Are the Top American Jeans Brands and Their Origins?

Snippet: Levi’s and Wrangler paved the way in North Carolina; Raleigh Denim Workshop and 3×1 craft in small batches; Good American—co-founded by Khloé Kardashian & Emma Grede—blends inclusive sizing with U.S. and overseas production.

Dive Deeper

4.1 The Originals: Levi’s & Wrangler

·Levi Strauss & Co.:

·Founded 1853, first mass producer; global Water<sup>Less</sup>™ tech saves up to 96% water in finishing.

·Established 1904; iconic for workwear durability.

4.2 Boutique Artisans

·Raleigh Denim Workshop (NC): 20–50 pair runs; full traceability from cotton to pocket.

·3×1 Denim (NYC): Fit labs downtown with on-demand wash customization.

4.3 Good American: Brand & Family

·Ownership & Ethos: Khloé Kardashian and Emma Grede launched Good American in 2016 to champion size inclusivity and body positivity.

·“Good American Family”: A community-driven feedback loop—customers, influencers, and designers co-create new fits.

·Manufacturing Footprint:

| Line | Location | MOQ |

| Selvedge Denim Series | Los Angeles, USA | 100 |

| Everyday Stretch Line | China/Vietnam | 500+ |

5. How Do Low-Minimum-Order and OEM/ODM Services Cater to Custom Denim Needs?

Snippet: Factories like DiZNEW enable MOQs as low as 30 pairs, offering turnkey OEM (your specs) and ODM (in-house designs) services—perfect for startups testing the market without huge inventory commitments.

Dive Deeper

| Run Type | MOQ Range | Per-Unit Cost | Best For |

| Standard Mass | 500–5,000 | $25–$35 | Established brands |

| Low MOQ | 30–100 | $40–$60 | Emerging designers |

| Ultra-Low Batch | 5–30 | $80–$120 | Exclusive limited-edition drops |

5.2 OEM vs. ODM: What’s the Difference?

·OEM (Original Equipment Manufacturer): Build exactly to your patterns, trims, and wash specs.

·ODM (Original Design Manufacturer): Pick from ready-to-go designs—shift focus to branding and marketing.

5.3 DiZNEW Workflow in Action

·Kickoff Call & Styling Moodboard: Share Pinterest boards; we fine-tune your vision.

·Pattern & Fit Sampling: 2–3 rounds, delivered in 10–14 days.

·Wash Approval: Choose from 12 standard washes or request custom enzyme/laser finishes.

·Full Production: 30–1,000 pairs; QC checks at 30%, 70%, and pre-shipment stages.

·Logistics & Packaging: From poly bags to branded hangtags, sorted per your specs.

6. Is Sustainability a Priority in U.S. Denim Manufacturing?

Snippet: Leading U.S. mills use laser fading, ozone washing, and recycled cotton content—cutting water use by 70–90% and reducing chemical runoff, all verified by third-party certifications.

Dive Deeper

6.1 Water & Chemical Savings

| Technology | Water Reduction | Chemical Reduction |

| Laser Fading | Up to 70% | N/A |

| Ozone Washing | 50–90% | Eliminates potassium permanganate |

| Enzyme Finishing | 30–60% | Minimal bleach use |

·Recycled Cotton: Up to 30% post-consumer content in premium lines.

·Organic Cotton: Grown without synthetic pesticides; used by mills in Texas and North Carolina.

6.3 Beware of Greenwashing

·Authentic Claims: Look for OEKO-TEX® Standard 100, Bluesign®, and GOTS certifications.

·Critical Lens: Brands lacking audits may overstate “eco-friendly” practices—always ask for data.

7. How Can Designers and Retailers Choose the Right U.S. Jeans Manufacturer?

Snippet: Evaluate partners by MOQ flexibility, lead time reliability, sustainability certifications, and clear communication—use a simple scoring matrix to compare factories side by side.

Dive Deeper

7.1 Selection Criteria & Weighting

| Criteria | Weight (%) | Why It Matters |

MOQ Flexibility | 20 | Tests styles affordably |

Lead Time | 25 | Meets seasonal launch deadlines |

| Sustainability | 15 | Aligns with brand values and customer demand |

| Certifications | 20 | Ensures quality, safety, and environmental compliance |

| Communication | 20 | Prevents costly misunderstandings |

7.2 Red Flags to Watch For

·MIA Factories: Slow email replies often flag production delays.

·Hidden Costs: Ask for all-in pricing—trims, packaging, and QC fees included.

7.3 Sample Decision Matrix

| Factory | MOQ Flexibility (20) | Lead Time (25) | Sustainability (15) | Certs (20) | Comm (20) | Total (100) |

| DiZNEW | 18 | 22 | 14 | 18 | 18 | 90 |

| Competitor A | 16 | 18 | 12 | 16 | 15 | 77 |

| Competitor B | 14 | 20 | 10 | 14 | 16 | 74 |

1.Are Good American jeans made in the USA?

While some Good American jeans are crafted in the USA using premium denim, others are imported – the brand prioritizes ethical manufacturing and transparent labeling, with 'Made in USA' styles clearly marked online to support conscious fashion choices.

2.Are there any jeans made in the USA

Several heritage brands like Levi’s, Carhartt, and Round House still craft durable American-made jeans, blending timeless denim craftsmanship with modern sustainable practices – check labels for 'Made in USA' tags or explore small-batch workshops reviving domestic manufacturing.

3.Who is Good American jeans made by?

Good American jeans were co-founded by Emma Grede and Khloé Kardashian, championing inclusive sizing and ethical production – their denim blends LA-based design with globally sourced sustainable materials, prioritizing body positivity and transparent manufacturing practices.

4.Why is Good American so expensive?

Good American jeans justify their premium pricing through high-quality, sustainable fabrics, ethical manufacturing with fair wages, and inclusive sizing innovation – their commitment to body diversity and transparent supply chains elevates costs but aligns with values-driven, long-lasting denim investments.

Conclusion

Ready to turn these insights into your own custom denim success story? Reach out to DiZNEW today to get a detailed quote and start crafting your next signature jean—whether it’s a small 30-piece run or a large seasonal drop, you’ll get top-tier U.S. craftsmanship with an eco-friendly edge. Let’s make your American denim dreams come true!