Top Jeans Manufacturers | Reliable Denim Suppliers Guide

How to reach bast jeans manufacture?

In today's denim-obsessed world, finding the perfect factory partner feels like winning the lottery—you know the prize is out there, but the search can be rough. Whether you’re launching a streetwear label, workwear line, or festival-ready flares, your jeans's soul lives in the mill.

Featured Snippet: To reach the best jeans manufacturer, zero in on factories with high-tech looms, ISO/OEKO-TEX certifications, transparent supply chains, eco-friendly wash processes, low MOQs from 30 pieces, and fast sample-to-production timelines—then validate via audits, samples, and real client feedback.

1. What makes a jeans manufacturer the best choice for quality and reliability?

Featured Snippet: The best jeans factories combine cutting-edge shuttle looms, ISO/OEKO-TEX certifications, robust in-line inspections, and an R&D team that nails washes, fits, and finishes under tight deadlines.

Dive Deeper

1.1 Advanced Machinery Mix

Shuttle vs. Projectile Looms: Shuttle looms craft that coveted selvedge edge but run at ~30 meters per hour. Projectile looms crank out 200+ m/h at lower cost but no selvedge.

Automated Stitching Robots: These can cut cycle times by up to 25% on bartacks and belt loops—yet hand-finished details still command the premium tag.

1.2 Key Certifications & Audits

| Certification | What It Means | Why It Matters |

| ISO 9001 | Quality-management system | Consistent processes, fewer defects |

| OEKO-TEX | Harmful-substance testing in textiles | Safe for skin, eco compliance |

| Bluesign | Complete resource-friendly textile production | Reduces chemicals, water, energy |

Pro tip: Don't just ask for certificates—request the latest audit report summary. It gives you insights into recurring non-conformities.

1.3 R&D & Sample Speed

Fabric Lab Testing: Leading mills test for stretch recovery (up to 50,000 rubs on Martindale machines) and colorfastness in multi-climate chambers.

Rapid Prototyping: Top-tier factories promise first sample in 7–10 days; the lag elsewhere can be 21–30 days. When trend cycles move at warp speed, every day counts.

2. Which regions or local suppliers should you reach out to for the best jeans manufacture in the world, near you, in the USA, and in Mexico?

Featured Snippet: Top global hubs are China, Italy, Turkey, USA, and Mexico. Locally, scout LA’s Garment District, Mexico’s León/Guanajuato clusters, or Turkey’s denim corridor to balance cost, quality, and lead times.

Dive Deeper

2.1 Global Hotspots at a Glance

| Region | MOQ Range | Lead Time | Specialty |

China | 30–100 | 30–45 days | Low MOQs, full-service OEM/ODM |

Italy | 100+ | 45–60 days | Luxury washes, artisanal trims |

| Turkey | 100+ | 40–50 days | Premium dyeing, mid-range pricing |

| USA | 50–150 | 45–75 days | “Made in USA” branding, samplers |

| Mexico | 30–80 | 20–35 days | Nearshore U.S., quick-turn runs |

2.2 USA—LA's Garment District & Beyond

·LA Garment District: Home to 200+ denim cutters and small-batch sewers. MOQs often 50–100 pairs, pricing ~$25–35/pair.

·North Carolina Mills: Heritage craft, smaller runs (50–75 pairs), but count on $40+/pair and 6–8 week turnarounds.

2.3 Finding “Near Me” Options

·Trade Shows: Denim Première Vision, Canton Fair, and Texworld USA.

·Online Platforms: Maker's Row (U.S.), Alibaba/Aliyun (Asia), and Intertex (Latin America).

·Prototyping Studios: Use local sewing studios to bridge your designs to full-scale factories—you’ll catch red flags early.

2.4 Mexico’s Rapid-Response Zones

·León & Salamanca: Originally leather hubs, now 150+ denim workshops nearports. You’ll get 30–50 MOQ, 20–30 day lead, and shipping to U.S. west coast in 2–4 days via LCL.

3. How do you find, evaluate, and choose the right denim clothing manufacturer or supplier for your clothing line?

Quickly screen candidate factories through online catalogs, industry exhibitions and peer recommendations; order small batch samples, or conduct on-site/online visits to inspect the quality of cutting, sewing, washing and other processes, and finally select the denim factory that best meets your brand needs.

Featured Snippet: Start with online directories, trade-show scans, and peer referrals. Then vet via sample orders, factory audits (or virtual walkthroughs), MOQs, pricing transparency, and client testimonials to secure the best fit.

Dive Deeper

3.1 Research & Shortlisting

①Directories: Alibaba, Global Sources, Fibre2Fashion—filter by “ISO” and “OEM.”

②Referrals: Ask fellow brands in industry Slack channels or LinkedIn groups.

③Trade Shows: Schedule meetings in advance; post-show, follow up within 48 hours.

3.2 Sample & Audit Process

·Mini-Run of 5–10 Prototypes: Tests cut accuracy, stitching quality, wash consistency, and packaging.

·Factory Visit or Virtual Tour: Look for clean floors, organized workstations, and modern upkeep. Check worker safety gear.

3.3 Pricing & MOQs

| Volume Tier | MOQ | Unit Price Est. | Notes |

| Low Run | 30 | $28–32 | Basic designs, minimal trims |

| Mid-Run | 100 | $18–22 | More wash options, logo embroidery |

| Bulk | 500+ | $12–15 | Cheapest per-unit, longer lead time |

Quick tip: Ask if they offer tiered pricing or trial pricing for first orders to reduce your risk.

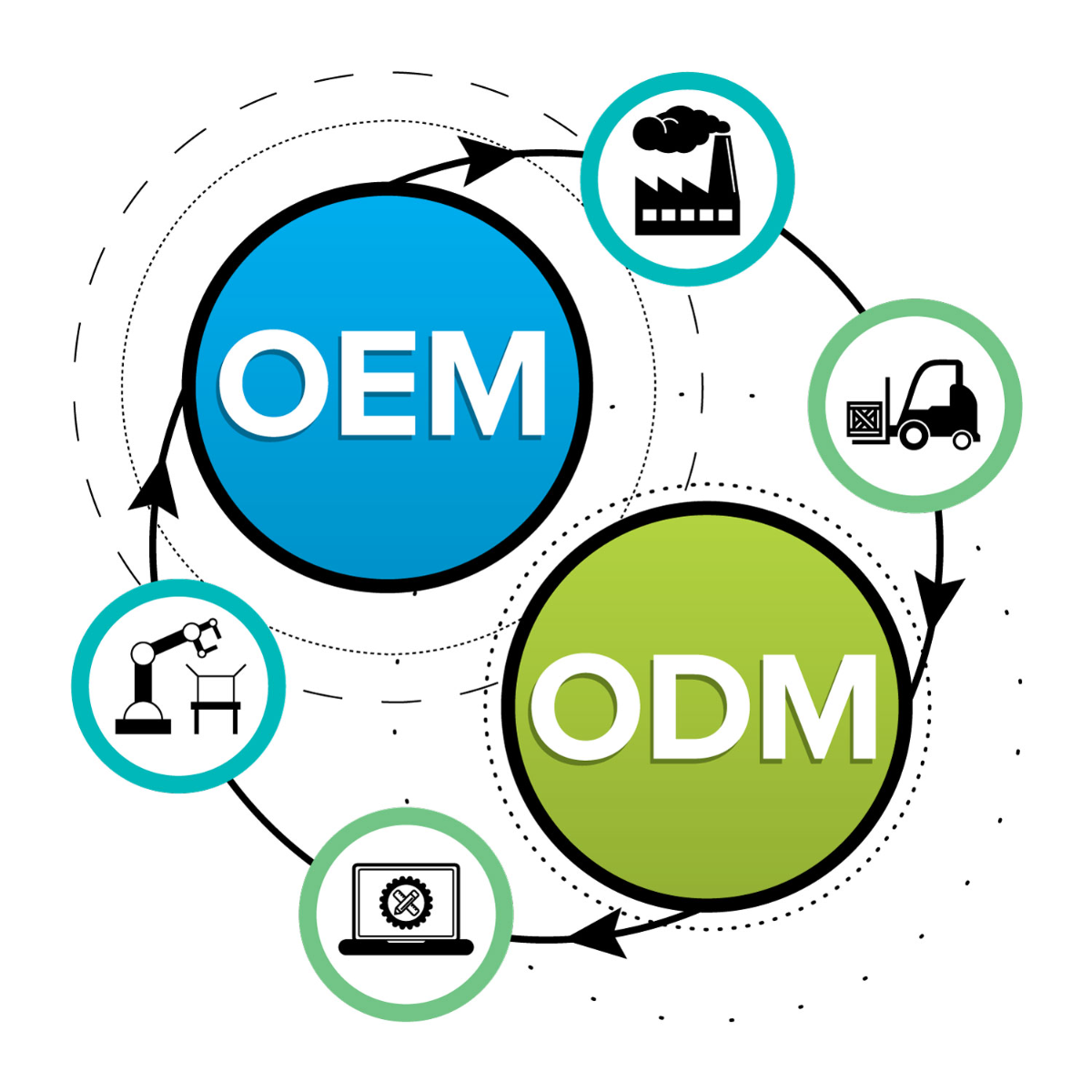

4. Are OEM, private-label, and ODM services essential for launching your jean brand with a low MOQ?

Featured Snippet: OEM, ODM, and private-label let you launch with MOQs as low as 30 pieces. OEM uses your designs, ODM uses factory's designs, and private-label blends both—ideal for limited budgets.

Dive Deeper

4.1 OEM vs. ODM vs. Private Label

·OEM: You bring the tech pack; factory executes. Full design control, but higher design fees.

·ODM: Factory offers ready-made designs; you just pick washes and add your label—faster, but less unique.

·Private Label: ODM foundation + small design tweaks—balanced cost, moderate exclusivity.

4.2 MOQ & IP Considerations

·OEM MOQs: Often 30–50 pieces; sometimes a $500–$1,000 design setup fee.

·ODM MOQs: Typically 100+; design fee baked into unit price.

·IP Protection: Sign an NDA and explicitly state in contracts that designs and tech packs are your property.

4.3 Budget-Friendly Strategy

·Use an ODM wash library to cut sample costs by up to 50%, then switch to OEM for your hero pieces once sales roll in.

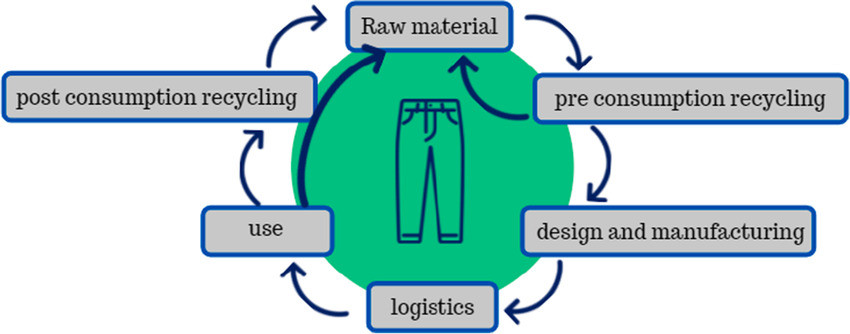

5. How do you manufacture jeans: understanding equipment, R&D, and sustainable practices?

OEM is suitable for people with original designs, ODM is faster and more cost-effective and suitable for start-ups, and Private Label balances uniqueness and cost, making it an ideal choice for those starting with a small budget.

Featured Snippet: Jeans production spans cutting, sewing, washing, and finishing. Key gear: ultrasonic cutters, laser/ozone washers, and closed-loop water systems. Enzyme finishes and recycled fibers can slash water use by 40–60%.

Dive Deeper

5.1 Cutting & Sewing

·Automated Cutters: Reduce fabric waste by 10–15%.

·Ultrasonic Welding: Seals edges without thread—ideal for lightweight stretch denim.

·Stitch Types: Triple-needle chain stitch for crotch seams yields 20% more strength versus lockstitch.

5.2 Wash & Finish Tech

| Technique | Water Savings | Turnaround | Look & Feel |

Pumice Stone | Baseline | 10–14 days | Authentic vintage, but high water |

| Laser Wash | 40–50% saved | 1–3 days | Sharp fades, eco-friendly |

| Ozone Wash | 50–60% saved | 2–4 days | Subtle fades, lower chemical use |

| Enzyme Finish | 30–40% saved | 5–7 days | Soft hand, less abrasion |

5.3 Sustainable Fiber & Dye Sourcing

·Organic Cotton: Grown without pesticides; costs +10–15% but resonates with eco-minded consumers.

·Recycled Denim: Post-consumer cotton blends cut landfill waste by up to 90%.

·Eco Dyes: Natural indigo or low-impact synthetic dyes reduce COD (chemical oxygen demand) in wastewater.

6. What cost factors, negotiation strategies, and ordering processes should you consider when buying custom jeans?

When customizing jeans, you need to consider cost factors such as fabric, washing process, order quantity, and LOGO printing.

Featured Snippet: Major cost drivers are fabric (40%), labor (30%), trims (15%), finishing (10%), overhead (5%). Negotiate on batch size, seasonal discounts, and payment terms (e.g., 30% deposit, 70% on delivery) to optimize cash flow and pricing.

Dive Deeper

6.1 Cost Breakdown

| Component | % of Total Cost | Example Cost per Pair |

Fabric | 40% | $5.00 per yard |

Labor | 30% | $8.00 |

| Trims & Hardware | 15% | $1.50 |

| Washing & Finishing | 10% | $2.00 |

| Overhead & Profit | 5% | $3.00 |

6.2 Smart Negotiation Tactics

·Volume Upsell: Bump MOQ by 20% to shave 10% off unit price.

·Off-Peak Deals: Factories run slower in Q2; ask for a 5–7% discount then.

·Payment Splits: Propose 30/70 or 40/60 to lessen your upfront cash burden.

6.3 Streamlined Ordering Workflow

·Tech Pack: Include flat sketches, spec sheet, fabric swatches, stitch samples.

·PO & Contract: Clearly outline lead times, penalties for delays, and IP clauses.

·Trade Assurance: Use Alibaba or sourced PLM tools to track POs and payments.

7. How can you ensure stringent quality control and on-time delivery for your custom jeans?

Featured Snippet: A multi-stage QC system—Pre-Production Approval (PPA), in-line inspections at 30/60/90%, and final AQL 2.5 checks—plus clear SLAs with penalties, keeps defects under 2.5% and deliveries on schedule.

Dive Deeper

7.1 Staged Inspection Protocols

·PPA: Sign off on complete sample—fabric, fit, hardware—before bulk cutting.

·In-Line Checks: Inspect 10–15 random pieces at key milestones (cutting, sewing, wash).

·Final Random Inspection: AQL 2.5 standard to limit defects under 2.5% of total order.

7.2 KPIs, SLAs & Penalties

| KPI | Target | Penalty if Missed |

| On-Time Delivery | 100% orders by ETA | 5% price deduction/week |

| Defect Rate | ≤ 2.5% | Rework at factory expense |

| Sample Approval Time | ≤ 10 days | $10/day compensation |

·QR Code Bundles: Scan to see cut-to-sew progress live.

·Dashboard Portals: Factories share daily yield reports, wash yields, and shipping statuses.

8. How do you market your custom jeans to stand out in various scenarios?

Position your jeans in different scenarios such as street fashion, concerts, parties or outdoor workwear, and create a differentiated image through social media short videos, KOL outfits, brand story marketing, etc.

Featured Snippet: Tailor promos: streetwear via micro-influencers on TikTok, workwear through trade mags, festival styles with pop-up activations. Leverage storytelling around your factory’s sustainable edge and customer testimonials for authentic buzz.

Dive Deeper

8.1 Scenario-Specific Campaigns

·Street & Social: Host Reels challenges—ask followers to style your raw denim.

·Workwear & Outdoor: Co-author articles in Construction Today or Gear Patrol on durability tests.

·Events & Music Festivals: Set up on-site custom patch booths and document it on IG Stories.

8.2 Collaboration & Influencer Models

·Limited Edition Drops: Partner with a local artist to hand-paint 50 pairs—create FOMO.

·Affiliate Programs: Offer 10% commission on tracked links; influencers bear no upfront cost.

8.3 Content & Experience Marketing

·“Mill to Market” Series: Short videos showing laser washers, enzyme tanks, and fabric sourcing—build transparency.

·Denim Care Workshops: Online webinars or live sessions on denim maintenance—positions you as the go-to expert.

1.How much does it cost to manufacture a pair of jeans?

The average cost to manufacture a pair of jeans ranges from 5 − 5−15, influenced by fabric quality (denim weight, organic cotton), labor costs (varies by country), production scale, and sustainable practices like recycled materials or waterless dyeing techniques.

2.Who manufactures the best denim?

Top denim manufacturers like Japanese selvedge denim mills (Kaihara, Kuroki), Italian heritage brands (Candiani), and American workwear specialists (Cone Mills) excel through premium raw materials, artisan craftsmanship (shuttle looms, rope-dyeing), and ethical practices—quality hinges on fabric weight, weave, and sustainable innovation like ozone washing.

3.Where is the perfect jeans manufactured?

The perfect jeans are crafted in Japanese denim hubs (Okayama), Italian artisan workshops (Prato), and American heritage factories (Los Angeles), blending premium selvedge fabric, heritage craftsmanship (hand-sanded finishes, vintage looms), and sustainable practices like laser distressing or organic indigo dyeing for durability and authenticity.

4.How much does it cost to get jeans made for you?

Custom jeans cost 150 − 150−600+ based on premium denim quality (selvedge/organic), design complexity (custom-fit patterns, handcrafted details), and brand expertise—luxury bespoke options exceed $1,000 for artisanal craftsmanship or sustainable materials like hemp blends.

Conclusion

Now it's time to turn insights into action. Reach out to DiZNEW today for a personalized consultation, a rapid prototype sample, and a turnkey OEM/ODM quote tailored to your brand’s needs. With our low MOQ of 30 pieces, advanced machinery, and eco-focused processes, we'll help you craft authentic, high-quality jeans—on time and on budget. Let’s make your denim dreams reality!