Start Clothing Manufacturing: 5 Key Steps for Beginners

How do you start clothing manufacturing?

Getting into clothing manufacturing feels like unlocking a secret world where creativity meets cold, hard machinery. You've seen that perfectly faded pair of jeans or that limited-edition streetwear drop, and wondered, “How do they actually make that?”

1.What is the current state of the clothing manufacturing industry and process?

Snippet: The $2.9 trillion global clothing manufacturing scene is fueled by fast fashion, small-batch customization, and booming sustainability. Core steps: design, sourcing, cutting, sewing, finishing, and distribution—with automation and eco-tech on the rise.

Dive Deeper

1. Fast Fashion vs. Slow Fashion

·Slow Fashion Movement: Labels such as Patagonia focus on durability and ethics, often charging a premium but cutting down landfill volume.

2. Process Stages Breakdown

| Stage | What Happens | Modern Twist |

Design & Tech Pack | Sketches, measurements, material specs | 3D CAD tools for virtual sampling |

Material Sourcing | Buying fabric, trims, buttons | Digital marketplaces, real-time lead times |

Cutting & Sewing | Manual or laser cutting; industrial sewing | Robotic sewing arms, zero-waste markers |

| Finishing | Washing, distressing, pressing | Waterless dyeing, laser distressing |

| Quality Control | AQL sampling, defect checks | AI-powered defect detection cameras |

| Logistics & Distribution | Packing, shipping to stores or direct to consumer | On-demand production, just-in-time delivery |

·Waterless Dyeing: Uses up to 90% less water than traditional vats.

·Closed-Loop Recycling: Textile scraps are reprocessed into new yarn.

·Digital Twins: Virtual garments let you catch fit issues before the first stitch.

2.Which elements should you include in a clothing manufacturing business plan?

Snippet: Your plan needs market research, competitive analysis, financial projections (plant and equipment costs), niche definition (OEM/ODM, 30-piece MOQs), supply-chain maps, and sustainability goals to guide investment through break-even.

Dive Deeper

1. Market Analysis for Startups

·Customer Personas: Boutique owners craving unique capsule collections; influencers looking for limited drops; eco-consumers demanding traceability.

·Competitor Scan: Local microfactories versus large offshore giants—each has different turnaround times, MOQs, and price points.

2. Financial Projections & Cost Breakdown

| Expense Category | Low Estimate (USD) | High Estimate (USD) | Notes |

Lease & Renovation | $50,000 | $120,000 | Depending on region and space condition |

Machinery & Equipment | $80,000 | $200,000 | From cutters to washers |

Initial Raw Materials (6 mos) | $30,000 | $60,000 | Fabric, trims, packaging |

| Staff Salaries (monthly) | $15,000 | $25,000 | 10–15 skilled workers |

| Utilities & Overhead (monthly) | $5,000 | $10,000 | Water, electricity, maintenance |

| Permits & Legal Fees | $2,000 | $5,000 | Zoning, environmental, business license |

3. Defining Your Niche

·OEM/ODM Partnerships: White-label production for established brands—they supply designs, you supply manufacturing muscle.

·Low MOQ (30 pcs): Attract indie designers who can’t commit to 500+ pieces.

·Application Scenarios:

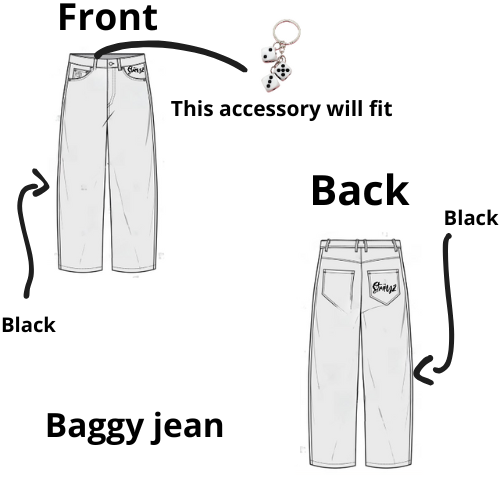

①Streetwear: Trend-driven washes and custom embroidery

②Workwear/Outdoor: Durable selvedge denim, reinforced stitching

③Events & Concerts: Flashy rhinestones, quick-turnaround distressing

·Water Use Metrics: Track liters per garment, aiming to cut 30% in year one.

·Supplier Audits: Quarterly checks for labor practices and environmental impact.

3.How do you start clothing manufacturing in the USA with a small factory?

Snippet: In America, form an LLC or Corp, get zoning and environmental permits, follow state labor laws, pick a spot in an industrial park, and team up with local suppliers to keep MOQs small and lead times tight.

Dive Deeper

1. Legal & Regulatory Must-Haves

Entity Formation: LLCs are popular for liability protection and pass-through taxation; S-Corps can save on self-employment taxes.

Key Permits:

·Zoning Permit: Ensures your location is factory-friendly

·Wastewater Discharge Permit: Especially important if you’re using water-based finishes

·OSHA Compliance: Safety training, proper ventilation, machine-guarding

2. Location & Facility Considerations

| Option | Pros | Cons |

| Industrial Park | Bulk utilities, shared services, networking | Higher rent in prime zones |

| Shared Makerspace | Lower entry cost, shared equipment access | Limited production volume, scheduling conflicts |

| Standalone Building | Full control, unlimited hours | High upfront renovation costs |

3. Scaling from Small Runs to Big Orders

·Modular Production Lines: Quickly swap from one style to another in under an hour.

·Case Study: A Denver startup began with 30-piece runs for local designers; within 12 months, they hit 500 orders a month by exhibiting at local pop-ups and trade events.

4.What does the typical garment manufacturing process look like (and where can I find a PDF guide)?

Snippet: You start with a tech pack and pattern, move through sampling, grading, cutting, sewing, and finishing. For in-depth PDFs, check out Fashiondex’s “Garment Manufacturing Process” and Apparel Search’s “How to Start a Clothing Factory.”

Dive Deeper

①Tech Pack Key Elements:

·Sketches & Flats: Front, back, side views with all details

·Measurements & Tolerances: Exact specs plus acceptable variances

·Material & Trim Specs: Fabric weight (GSM), button type, zipper length

②Pattern Making: Hand-draped samples vs. CAD-graded patterns for efficient scaling

2. Sampling & Fit Sessions

·Prototype Round: First sample for basic fit; expect 1–2 revisions.

·Pre-Production Sample: Final sign-off on color, wash, fit before bulk order.

3. Cutting & Sewing Operations

| Operation | Description | Time per Batch |

Marker Making | Nesting patterns to optimize fabric use | 1–2 hours (per style) |

| Cutting | Laser or manual cutting following the marker layout | 2–3 hours (30 pcs) |

| Sewing | Assembly: side seams, pockets, hems | 8–12 hours (30 pcs) |

| Finishing | Washing, distressing, pressing | 3–5 hours (full batch) |

①Washing Methods:

·Enzyme Wash: Softens denim with minimal damage

·Stone Wash: Classic worn-in look, but uses more water

·Waterless Systems: Super eco-friendly, uses CO₂ instead of H₂O

②Acceptable Quality Level (AQL):

·Inspect 10% of pieces per batch; maximum of 2 defects per 30 pcs

5. Handy PDF Resources

·"Garment Manufacturing Process"PDF: Detailed flowcharts, checklists, and case studies.

·"How to Start a Clothing Factory" PDF: Plant-setup checklists, equipment specs, and permit guidelines.

5.How do you source materials and machinery for a small-order apparel factory?

Snippet: Lock in sustainable denim and fabrics from certified mills, vet vendors through sample tests and audits, and invest in flexible machines—laser cutters, modular sewing, and eco-friendly washers—to handle small batches without quality loss.

Dive Deeper

①Key Fabric Specs:

·GSM (Grams per Square Meter): Denim usually 10–14 oz (~340–475 g/m²)

·Tensile Strength & Tear Resistance: Lab reports guarantee durability

②Certifications to Look For:

·GOTS: Global Organic Textile Standard

·OEKO-TEX® Standard 100: No harmful substances

2. Vendor Vetting Process

①Request Sample Yardage: Test for shrinkage, colorfastness, hand feel.

②Onsite or Remote Audit: Verify environmental and labor practices.

③Trial Production: Run a 10-piece mini-order to test lead times and consistency.

3. Machinery Essentials & Costs

| Machine Type | Function | Cost Range (USD) |

Automated Fabric Cutter | High-precision cutting, fabric nesting | $15,000–$30,000 |

| Multi-needle Sewing Machine | Decorative and reinforced seams | $5,000–$10,000 |

| Industrial Washer | Enzyme, stone, and CO₂ waterless washes | $20,000–$40,000 |

| Steam Tunnel | Quick, uniform pressing | $8,000–$15,000 |

4. Eco-Innovation Spotlight

·Waterless Dyeing Tech: Saves up to 90% of water compared to conventional vats.

·Closed-Loop Recycling Systems: Captures and reprocesses up to 95% of textile scraps.

6.How do you start a clothing brand or line from scratch?

Snippet: Building a brand means defining your unique selling point (USP), crafting a relatable story, designing a cohesive collection, creating branding assets, and choosing channels—D2C, marketplaces, or retail—to reach your ideal customer.

Dive Deeper

1. Crafting Your Brand Identity

①USP Brainstorm: Is it zero-waste production, artisan distressing, or hyper-custom fits?

②Narrative Elements:

·Founder’s personal journey

·Sustainability mission with real metrics (e.g., 60 L water saved per garment)

·Community impact (local hiring, charity partnerships)

2. From Moodboards to Line Sheets

①Moodboards: Pinterest-style collages showing color palettes, textures, and inspirations.

②Line Sheets: One-page visuals with images, style numbers, size runs, wholesale/pricing—crucial for buyer pitches.

3. Go-to-Market Channels

①E-Commerce Platforms: Shopify for turnkey setup; BigCommerce for B2B features; custom site for full control.

②Social Proof:

·Micro-influencer unboxings and try-ons

·User-generated content campaigns (e.g., #MyDIZNEWFit)

③Retail & Pop-Ups:

·Short-term retail spaces in key neighborhoods

·Collaboration events with local cafés or galleries

7.What strategies help you launch and grow your clothes business?

Snippet: Scale smart by forging OEM/ODM partnerships, creating SEO-rich content (blogs, FAQs), joining trade shows, gathering real-time feedback, and constantly optimizing processes—especially for water and waste—to build a brand that lasts.

Dive Deeper

1. Strategic Alliances

①OEM/ODM Collaborations:

·Exclusive capsule collections with emerging designers

②Co-Manufacturing Networks: Sharing idle capacity to reduce costs and speed up delivery

2. Digital Marketing & SEO Tips

| Tactic | Why It Works |

Content Marketing | Drives organic traffic—“How to start clothing manufacturing” blog posts |

| Keyword Optimization | Target long-tail phrases: “low MOQ denim manufacturers” |

| Email Automation | Nurtures leads—welcome series, abandoned cart reminders |

| Social Ads & Retargeting | Keeps your brand top-of-mind after site visits |

3. Trade Shows, Pop-Ups & Events

·Texworld & Apparel Sourcing LA: Showcase capabilities to hundreds of buyers and media.

·Local Pop-Ups: Collaborate with lifestyle brands—coffee shops, galleries—to reach niche audiences.

4. Continuous Improvement Metrics

①Lead Time Tracking: From order to ship—aim for under 30 days for small runs.

②Defect Rate Monitoring: Keep below 2% defects per batch.

③Sustainability KPIs:

·Water Use per Garment: Target under 50 L in year one

·Waste Diversion Rate: Recycle or repurpose 80% of scraps

FAQ'S

1.How much does it cost to manufacture your own clothes?

The average cost to manufacture your own clothing line ranges from 500–5,000+ for small batches, depending on fabric quality, labor, design complexity (like custom patterns or prints), production scale (cutting costs per unit at higher volumes), and location (local vs. overseas factories) – sustainable materials or ethical manufacturing often add 20–40% to base costs.

2.How much does it cost to start a line of clothing?

The cost to start a clothing line typically ranges from2,000–20,000+, driven by fabric sourcing, sample development (prototypes cost150–500 each), minimum order quantities (MOQs), production location (overseas factories cut costs by 30–60% vs. local), and marketing budgets – eco-friendly materials add 25–50% but align with rising demand for sustainable fashion.

3.How do clothes get produced in factories?

Clothes production in factories follows a 6-step process: design prototyping (2–4 weeks), fabric cutting (laser-guided for precision), assembly line sewing, quality control (AQL inspections reject 5–15% of units), labeling/packaging, and bulk shipping – modern factories now integrate sustainable practices like waterless dyeing or AI-driven pattern optimization to reduce waste by 20–40%.

4.How do i start a quality clothing brand?

Launching a quality clothing brand requires niche market research (4–6 weeks), premium fabric sourcing (organic cotton costs 30–50% more), small-batch production (MOQs of 50–100 units), rigorous quality control (3–5% defect rate industry standard), and brand storytelling (70% of consumers prioritize values-aligned brands) – integrating sustainable certifications (like GOTS) boosts credibility and justifies 15–30% price premiums.

Conclusion

Starting a clothing manufacturing venture may seem daunting, but by breaking it down into clear steps—defining your niche, drafting a solid business plan, handling legal permits, sourcing top-notch materials, setting up efficient machinery, prototyping diligently, enforcing rigorous quality control, and rolling out smart marketing—you turn a big dream into a practical reality. Along the way, lean into sustainability and tech innovations (like waterless dyeing and digital sampling) to stand out and build lasting customer trust.

Every great factory started somewhere—often with just a handful of pieces and a passionate team. Whether you’re eyeing streetwear drops, rugged workwear runs, or eye-catching event apparel, DiZNEW is here to help. With our 30-piece low-MOQ, cutting-edge equipment, and green-minded processes, we’ll guide you from that first tech pack to shipping your very first collection.