Need Tech Packs for Clothing Business? | Expert Guide

Do I Need Tech Packs for My Clothing Business?

Launching a clothing brand—whether you’re starting a clothing line, launching an online boutique, or experimenting with drop shipping clothing—means turning wild ideas into real garments. But without a technical pack (aka tech pack, apparel tech pack, garment tech pack, or fashion tech pack), you’re basically sending your factory a sketch and hoping for the best.

1. What is a tech pack and how does it support the design-to-production process?

A tech pack is a detailed document—sometimes called a technical pack fashion spec or tech package—that captures every measurement, material, trim, and construction note so factories make your clothes exactly as you envisioned.

Dive Deeper:

1.Terminology & Purpose

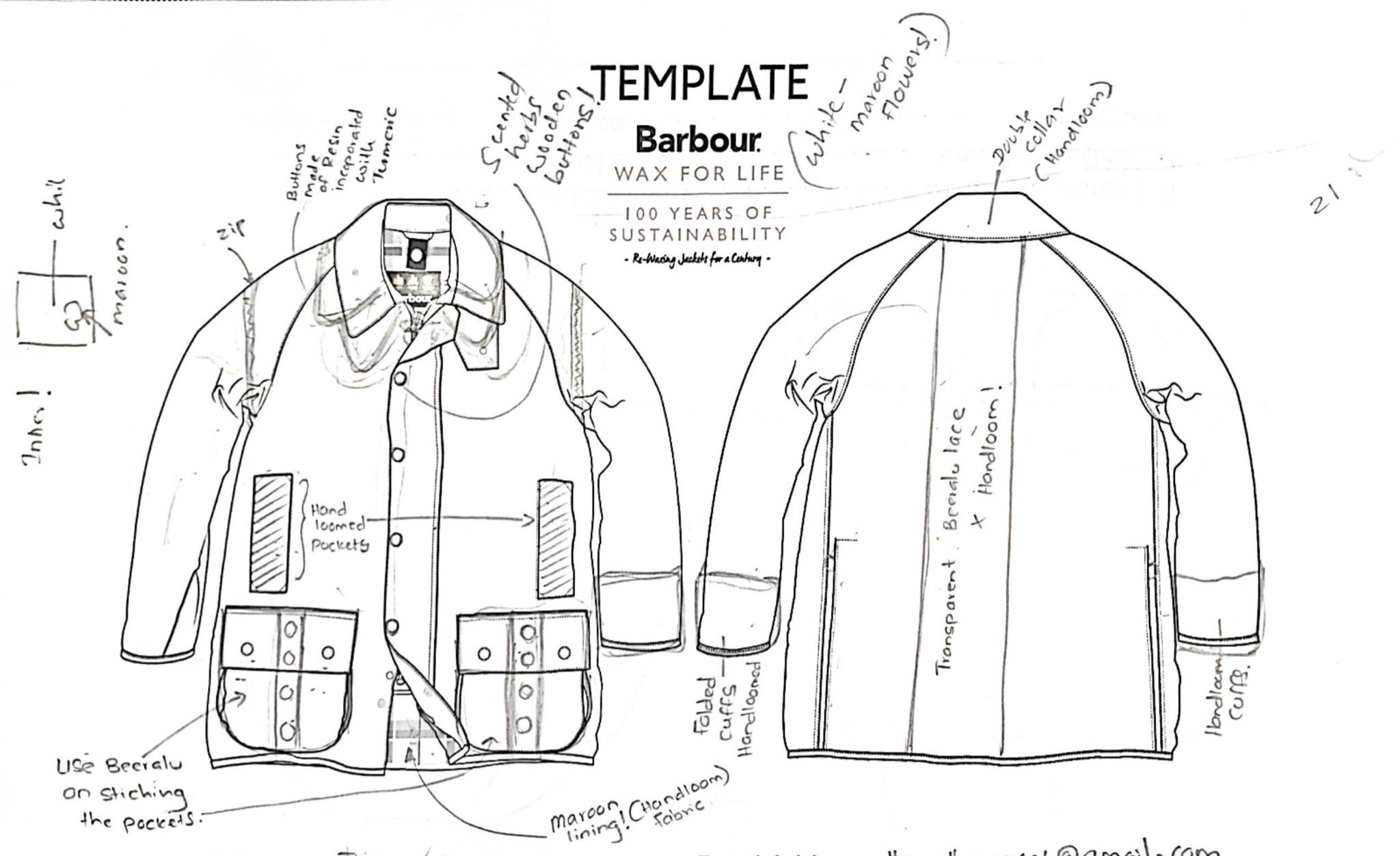

·Tech packs in fashion go by many names: clothing tech pack, tech pack garment, tec packs, tech pack fashion, technical pack, etc. All serve the same mission: translate style sketches into manufacturing-ready specs.

2.Core Sections of a Clothing Tech Pack

| Section | Contents |

Style Sheet | CADs, sketches, moodboard images |

Measurements | Body and garment specs, tolerances (cm & in) |

Materials & Trims | Fabric names, weight, color codes, zippers, buttons, labels |

| Construction Notes | Stitch density, seam allowances, bartack locations |

| Artwork & Embroidery | Vector files, placement diagrams |

| Packaging & Labels | Hangtags, polybag sizes, carton art |

3.From Idea to Sample

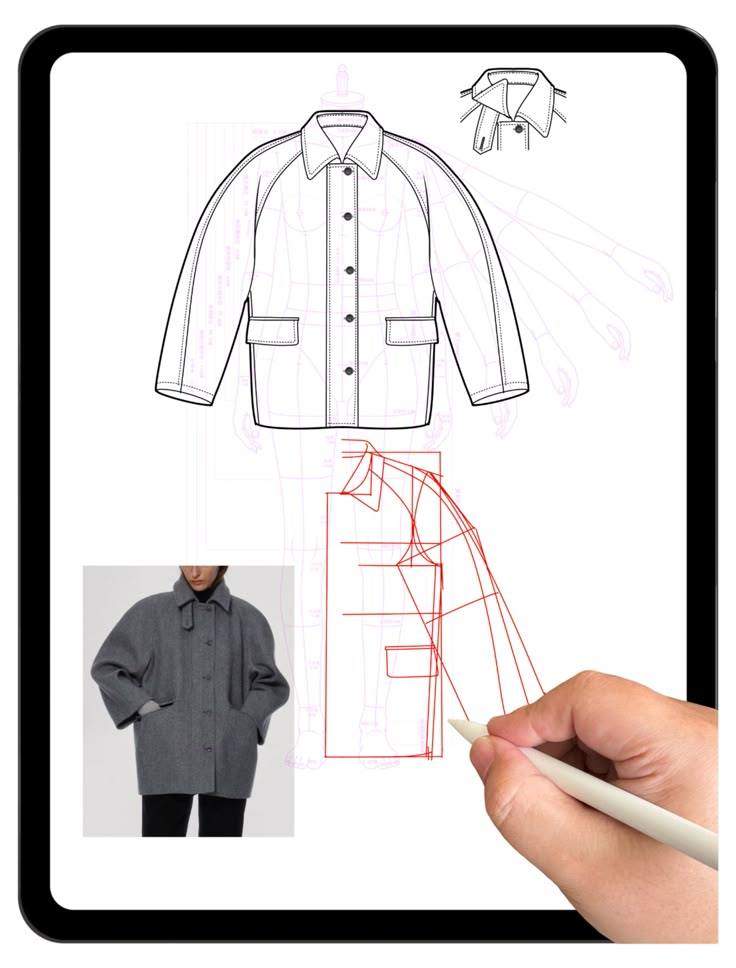

·Sketch your T-shirt tech pack on paper or Illustrator, then build out each table: fabric swatch photos, tech pack of t shirt color references, and your tech pack sample notes.

Example: a garment tech pack PDF from DiZNEW used 12 oz Japanese denim swatches plus copper rivet callouts to nail the first sample.

4.Why It Accelerates Startups

Brands who skipped tech packs spent over 5 rounds of samples on average; those with a pack landed in 1–2 rounds, saving 60% of sampling time.

2. Why are tech packs essential for effective OEM/ODM collaboration?

A detailed tech pack bridges your brand’s vision and the factory’s workflow—ensuring every stitch, trim, and finish matches your expectations and eliminating costly misunderstandings with your OEM/ODM partner.

Tech packs act as the universal “factory language,” ensuring your tech pack designer instructions on fit, trims, and finishes are crystal-clear—eliminating costly miscommunications with dropshipping clothing suppliers or overseas partners.

Dive Deeper:

1.Bridging Creative & Manufacturing Worlds

·A tech pack designer (in-house or freelance) assembles your tech pack example—complete with photos of your first prototype and detailed revision notes.

2.Setting Quality Gates

·Use tech pack sample checkpoints:

①Initial sample review

②Pre-production sample approval

③Bulk production sign-off

3.Case Study: Drop Shipping Meets Tech Packs

·An entrepreneur using drop shipping clothing on their Shopify store lost sales because shirts arrived with wrong logos. After implementing a tech pack for clothing, their print on demand t shirt company hit 98% accuracy.

4.Cost & Time Predictability

·Clear specs transform hidden fees into line-item costs and compress lead times—critical when you're starting an online clothing store ahead of a seasonal launch.

3. How do tech packs reduce production errors and control costs?

By detailing every measurement, material, and construction note upfront, tech packs slash sampling rounds and prevent costly production mistakes, keeping your timelines and budgets on target.

By spelling out every detail—from stitch density to bag tech pack hardware—you slash sample revisions, cut out wasted fabric, and lock in production pricing for your apparel tech pack, boosting your bottom line.

Dive Deeper:

1.Data-Backed Error Reduction

·DiZNEW’s clients using free tech pack templates saw a 60% drop in fit and trim errors; those on techpacker SaaS platforms cut revisions by 75%.

2.Sampling Cost Breakdown

| Metric | Before Pack | After Pack | Savings |

| Sampling Rounds per Style | 4 | 1.6 | 60% fewer |

| Avg. Cost per Round (USD) | 60 | 60 | - |

| Total Sampling Cost per Style | 240 | 96 | USD 144 saved |

3.Hidden Savings

·Fewer hat tech pack errors mean no overnight shipping surcharges.

·Nail your sweatshirt tech pack in one go and avoid restocking charges.

4.Real-Time Updates with Techpacker

·Tools like Techpacker let you comment live on specs—no more “I never got your email” excuses.

4. Which components and specifications are mandatory in a detailed tech pack?

Every robust tech pack must include style code, full measurement chart, sweatshirt tech pack stitch notes, hat tech pack seam allowances, bag tech pack hardware list, color codes, and revision history to keep everyone on the same page.

Dive Deeper:

1.Measurement Chart Essentials

| Measurement | S (cm/in) | Tolerance |

| Chest | 90 cm / 35” | ±0.5 cm |

| Shoulder | 40 cm / 15.7” | ±0.3 cm |

| Sleeve Length | 62 cm / 24.4” | ±0.5 cm |

2.Material & Trim Calls

·Technical pack calls out:

·“12 oz denim (98% cotton/2% elastane)”

·“Antique brass YKK #5 zipper”

·“Custom woven label, 50×15 mm”

3.Construction & Stitching

·Stitch density: 20 st/cm

·Seam allowance: 1 cm French felled

·Bar tack at stress points (pocket corners, hem joins)

4.Accessory-Specific Sections

·Bag tech pack: hardware finish, strap adjuster specs

·Hat tech pack: panel dimensions, sweatband material

5.Revision Log

| Date | Editor | Change |

| 2025-04-15 | J. Wang | Updated pocket depth from 14→16 cm |

| 2025-04-18 | M. Lee | Swapped copper rivets for brass |

5. How can digital tools and templates streamline tech pack creation?

Whether you grab a free tech pack template or subscribe to techpacker, digital solutions let you auto-generate PDF or Excel packs, track versions, and collaborate with your tech pack designer, slashing creation time by 50%.

Dive Deeper:

1.Top Tech Pack Software & Templates

| Tool/Template | TypeSaaS | Cost | Highlight |

Techpacker | SaaS | $25/mo | Live spec collaboration |

CLO 3D | Desktop | $85/mo | 3D prototyping |

| Illustrator + Plugin | Desktop | $20.99/mo | Vector-based spec drawing |

| Free Excel Template | Download | Free | Quick start with formula support |

| Custom | Custom | Tailored OEM/ODM workflow |

2.Building Your Own Template

·Use Excel or Google Sheets: add formulas to auto-calc grade rules, conditional formatting to flag out-of-range measurements.

·Export as garment tech pack PDF or tech pack example Excel for easy sharing.

3.Integration with 3D Sampling

·Tools like CLO 3D or Browzwear let you preview your tech pack sample on virtual models—catch fit issues before cutting fabric.

4.Free vs. Paid: What’s Right for You?

·Free tech pack downloads cover basics—great for clothing brand startup on a budget.

·Paid platforms (Techpacker, CLO) pay off when you scale or need strict revision history and audit trails.

6. Do low-volume orders (e.g., 30-piece MOQs) require the same level of tech pack detail?

Even if you’re ordering a small batch—whether you’re dropshipping clothing or using print on demand t shirt companies—a lean tech pack with core specs prevents mistakes and keeps costs low.

Dive Deeper:

1.Full vs. Lean Packs

| Feature | Full Pack | Lean “Mini” Pack |

Measurement Chart | ✓ | ✓ (core sizes only) |

Materials & Trims | ✓ | ✓ (critical items) |

| Construction Notes | ✓ | Minimal |

| Revision Log | ✓ | Optional |

| Packaging Specs | ✓ | Default DiZNEW setup |

2.Case Study: 30-Piece Starter Kit

·A pop-up brand used our mini-tech pack—just 8 fields—for best clothes selling app orders and nailed their first drop with zero revisions.

3.Dropshipping & Print-On-Demand

·When you start your own clothing line via Shopify stores clothing or partner with dropshipping clothing suppliers, a clear t shirt tech pack ensures the best t shirt printing company hits your ink density and logo placement precisely.

4.Scaling Your Pack

·At 100+ pieces, or when adding complex details (embroidery, hardware), shift to a full apparel tech pack to protect your margins.

7. Are tech packs aligned with sustainable and efficient manufacturing practices?

Tech packs support sustainable and efficient manufacturing by minimizing waste, optimizing material usage, and reducing unnecessary revisions—helping brands lower their environmental impact while speeding up production.

Clear tech packs optimize fabric usage, specify technical pack fashion dyes, and call for eco-certified materials—slashing waste, cutting water use, and supporting your brand’s green credentials.

Dive Deeper:

1.Precise Yardage Calculations

| Fabric Type | Ordered (yd) | Used (yd) | Waste (yd) |

| 12 oz Denim | 100 | 92 | 8 |

| Recycled Chambray | 80 | 76 | 4 |

2.Water-Saving Dye Methods

·Specify low-liquor-ratio rope dye or ozone finishing to cut water use by up to 70%.

3.Eco-Material Callouts

·GOTS-certified organic cotton, recycled polyester wefts, compostable polybags.

4.Going Digital

·A cloud-based tech package means no printed packets—reducing paper and your carbon footprint.

1.Are tech packs necessary?

Yes, tech packs are essential for streamlining production, reducing errors, and ensuring consistent quality; they serve as a blueprint for manufacturers and are critical for cost-effective, efficient fashion design and manufacturing processes.

2.Why is tech pack important in garment industry?

Tech packs are crucial in the garment industry as they consolidate design specs, material requirements, and quality standards into a single document, ensuring seamless factory communication, minimizing costly revisions, and enabling scalable, error-free production of clothing lines.

3.How much does a fashion tech pack cost?

Fashion tech packs typically cost between 200−2000+ depending on design complexity, technical drawings, and material specifications, but they save long-term expenses by reducing sampling errors, accelerating approvals, and securing accurate manufacturing quotes for scalable garment production.

4.How do you make a tech pack for clothes?

Create a professional tech pack for clothes by including flat sketches, measurement specs, material lists, construction details, and size charts—these factory-ready templates ensure design accuracy, minimize sampling errors, and streamline bulk production for seamless manufacturer communication.

Conclusion

Whether you're starting my own clothing line, exploring clothes selling websites, or building your online clothing business, tech packs are nonnegotiable. They:

·Speed up production (1–2 sample rounds vs. 4+ rounds)

·Slash costs (save 60% on sampling alone)

·Ensure quality (precise specs for any bag tech pack, hat tech pack, or sweatshirt tech pack)

·Support sustainability (optimize yardage and water use)

Don't leave your designs to chance or rely on “winging it” with dropshipping clothing suppliers or print on demand t shirt companies. Contact DiZNEW today—we're your go-to tech pack designer for custom OEM/ODM solutions, from 30-piece MOQs to 30,00+. Let’s get your next denim or street-style collection perfect the first time!