Men's Rayon/Spandex Jeans Brands | Top Stretch Denim Companies

What companies make men’s jeans with rayon or spandex?

In today's denim world, it's all about marrying style with comfort—no one wants stiff, scratchy jeans that wear out in a snap. That's why more and more brands are weaving rayon or spandex into their men’s denim, delivering that perfect blend of stretch, softness, and shape retention.

1.What Are the Performance Advantages of Adding Rayon or Spandex to Men’s Jeans?

Snippet : Adding 1–5% rayon/spandex to denim enhances stretch (up to 30%), recovery, drape, and breathability—resulting in jeans that move with you, resist bagging at the knees, and stay comfortable all day long.

Dive Deeper

1.Stretch & Snap-Back

·Data Point: Spandex-enhanced denim can stretch up to 30% more than rigid cotton and recover over 90% of its original shape after 20 wears.

·Why It Matters: You get freedom to move—sitting, squatting, or dancing—without baggy knees or saggy waistbands.

2.Soft Drape & Silhouette

·Role of Rayon: Viscose-rayon mimics silk’s smooth hand-feel, so your jeans drape naturally around your legs instead of feeling boxy.

·Real-World Example: A slim-fit jean with 3% rayon blend feels as soft as loungewear but holds a sharp, tailored silhouette.

3.Moisture Wicking & Breathability

·Tech Insight: Rayon fibers pull sweat away from skin, drying faster than pure cotton—ideal for hot days or outdoor events.

·User Feedback: Festival-goers report staying drier and cooler in spandex/rayon blends compared to 100% cotton pairs.

4.Durability Trade-Offs

·Sweet Spot: Most experts recommend 2–5% stretch fiber content—enough for comfort but maintaining denim’s legendary toughness.

·Critical Note: Overloading spandex (>10%) can lead to early fiber fatigue; brands balance performance with longevity.

2.Which Leading Brands and Manufacturers Offer Men’s Jeans Blended with Rayon or Spandex?

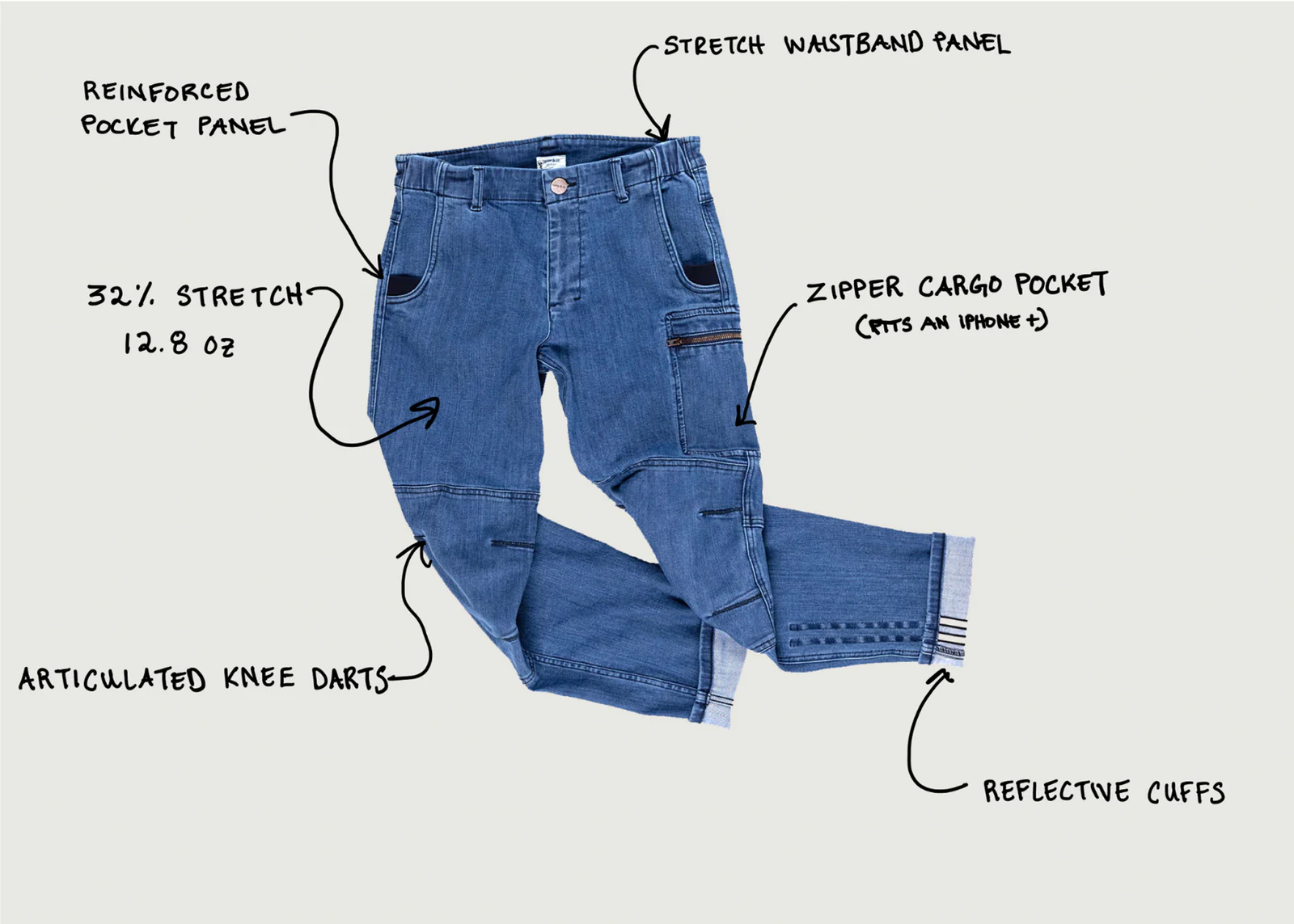

Levi’s and Wrangler (~2% spandex), AG Jeans (1.5% rayon + 2.5% spandex), Mugsy (up to 4% spandex), boutique labels like Nudie, Uniqlo, Edwin (1–3% spandex), and OEM/ODM specialist DiZNEW (1–5% blends, MOQ 30) lead rayon/spandex denim.

Dive Deeper

1.Heritage Giants: Levi's & Wrangler

·Blend Specs: Typically 2% spandex in their “511 Slim” and “Texas Stretch” lines.

·Mass Appeal: Millions of pairs sold annually; stretch denim keeps classic fits modern.

2.Premium Innovators: AG Jeans & Mugsy

·AG Jeans “Graduate” uses 1.5% rayon + 2.5% spandex, offering a soft hand and four-way stretch.

·Mugsy Jeans MVP Line: Up to 4% spandex, targeted at men seeking athleisure-meets-denim.

3.Boutique & Global Pants Brands

| Brand | Origin | Stretch Blend | MOQ* | Specialty |

Nudie Jeans | Sweden | 1–2% Spandex | 100 pcs | Organic cotton; free repairs |

| Uniqlo | Japan | 2% Spandex | 300 pcs | Affordable, everyday essentials |

| Edwin | Japan | 2–3% Spandex | 200 pcs | Vintage-inspired craftsmanship |

| DiZNEW OEM | CHINA | 1–5% Rayon/Spandex | 30 pcs | Full OEM/ODM; low MOQ customization |

4.Jeans Brand From Different Countries

·Europe: Emphasize ring-spun cotton + elastane for premium feel.

·Asia: Blend rayon for cost-effective softness in fast-fashion and custom runs.

5.Company Names & OEM/ODM Specialists

·Brands like DiZNEW manufacture for over 50 private labels, integrating rayon/spandex under client brand tags.

3.How Are Rayon and Spandex Fibers Integrated into the Denim Production Process?

Snippet : Fiber blends happen at the yarn stage—either via core-spun or blended spinning—followed by precision weaving, enzyme or laser finishing, and heat-setting to lock in elasticity and consistent stretch across the fabric.

Dive Deeper

1.Yarn Blending Methods

·Core-Spun Yarn: Spandex filament wrapped in cotton for targeted stretch—common in waistbands and seams.

·Blended Yarn: Rayon or spandex mixed into cotton slivers prior to spinning, creating a uniform, all-over stretch.

2.Weaving vs. Knitting

·Woven Stretch Denim: Standard for four-way stretch when paired with spandex; retains denim’s authentic look.

·Knit Denim: Less common due to cost—delivers ultimate flexibility but softer “sweatpant” vibe.

3.Finishing Treatments

·Enzyme Washes: Bio-based enzymes break down stiffness gently, saving up to 50% water vs. stone washes.

·Laser Distressing: Precision wear patterns without water waste.

·Heat Setting: Ensures spandex fibers stabilize, preventing post-wash shrinkage over 5%.

4.Specialized Looms & Equipment

·High-Speed Sizing Machines: Prevent rayon/spandex yarn slippage during weaving.

·3D CAD Fit Simulators: Virtually preview how blend percentages affect drape and recovery

4.Which OEM/ODM Denim Factories Provide Custom Rayon/Spandex Jeans with Low Minimum Orders?

·Snippet : Factories like DiZNEW welcome orders starting at 30 pcs, offering end-to-end OEM/ODM—from digital tech packs and prototyping to mass production, QC, and global shipping—perfect for indie labels and small boutiques.

Dive Deeper

1.Low MOQ Advantages

·Step 1: Submit digital tech pack (fabrics, stitch details, fiber blend).

·Step 2: Proto sample within 10–14 days using 3D prototyping.

·Step 3: Fit trial feedback loop—typically 2–3 iterations.

·Time Saved: Up to 30% faster than traditional sampling cycles.

3.Batch Tracking & QC Labs

·Batch Codes: Each 30–100 piece run is tagged and tested for yarn consistency, stretch % and color uniformity.

·In-House Lab Metrics:

| Test | Standard | DiZNEW Result |

| Stretch Recovery | ≥ 90% after 20 cycles | 92–95% |

| Wash Shrinkage | < 5% | 3–4% |

| Colorfastness (Launder) | Grade 3–4 | Grade 4 |

·Consolidated Shipping: Lowers costs and carbon footprint.

·Just-In-Time Production: Reduces overstock and warehousing needs.

5.Do Quality Control Systems Differ for Stretch-Enhanced Denim?

Snippet: Absolutely—stretch denim undergoes specialized elasticity, recovery, wash durability, and abrasion tests (ASTM D3107, ISO 105-C06) to ensure performance fibers hold up under real-world wear and repeated laundering.

1.Elasticity & Recovery (ASTM D3107)

·Procedure: Stretch sample to 50% of original length 10 times, measure rebound.

·Benchmark: Elite factories achieve ≥95% rebound; low-tier mills often reach only 80–85%.

2.Wash Durability & Colorfastness (ISO 105-C06)

·Simulated Laundering: 5–10 cycles in controlled lab conditions.

·Finding: Rayon blends risk slight pilling if not enzyme-washed properly; top OEMs use optimized wash recipes.

3.Abrasion & Tensile Strength

·Martindale Test: Denim must endure ≥10,000 rub cycles without significant wear.

·Seam Strength: Ensures pockets and belt loops handle stretch without popping stitches.

4.Industry Best Practices

·Smaller Mills'Pitfall: Skipping recovery tests leads to customer returns.

·Pro Tip: Partner with factories that publish their QC metrics—not just marketing claims.

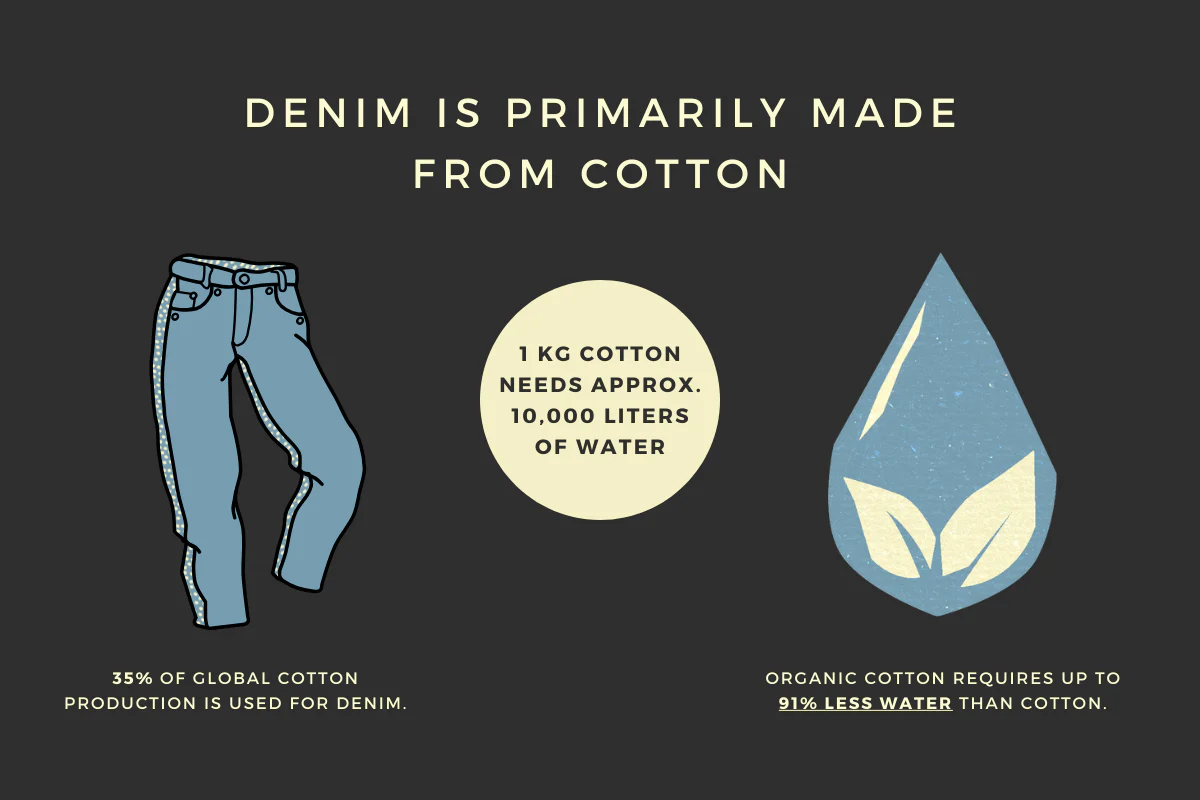

6.Is the Use of Rayon and Spandex in Jeans Compatible with Sustainable Manufacturing Goals?

Snippet : When coupled with eco-friendly fibers (e.g., Lenzing™ viscose), low-water ozone/laser washes, and closed-loop recycling, rayon/spandex blends can support sustainability—cutting water use by up to 70% and solvent discharge by 95%.

Dive Deeper

1.Responsible Rayon Sourcing

·Lenzing™ Viscose: Made from FSC-certified beechwood, with 95% solvent recovery in closed-loop processes.

·Certifications: OEKO-TEX® Standard 100 for low chemical residues.

·Ozone Finishing: Uses 50–70% less water than stone washes.

·Laser Techniques: Zero-water distressing, precise abrasion patterns

3.Challenges at End-of-Life

·Blend Recycling: Separating spandex is tricky; emerging chemical recycling methods (e.g., depolymerization) are promising but not yet mainstream.

·Critical View: Brands must plan for circularity—consider “take-back” programs or mono-fiber denim for full recyclability.

4.Case Study: Jeans Hong Kong

·Leading Hong Kong mills install solar panels on their laundries and recycle 80% of wash water—proof that stretch denim can be green.

7.How Can Fashion Brands Partner with Expert Factories to Develop Custom Rayon/Spandex Men’s Jeans?

Snippet : Successful partnerships hinge on clear tech packs, joint R&D, digital fit reviews, and iterative sampling—resulting in rayon/spandex jeans that meet design, performance, and eco-goals before scaling production.

Dive Deeper

·Fiber Percentages: Specify exact % stretch content (e.g., 3% spandex, 2% rayon).

·Stitch Details & Trims: Define thread type, rivets, and labeling for quality consistency.

2. 3D Prototyping & Fit Trials

·Virtual Reviews: 3D avatars simulate drape and stretch—eliminating up to 2 in-person fittings.

·Feedback Loop: Small edits (crotch rise, knee taper) implemented digitally before cutting yardage.

3.Scaling & Inventory Control

·On-Demand Runs: Produce 30–100 pieces per style based on real-time orders—minimizes deadstock.

·ERP Integration: Syncs order intake, production, and shipment for seamless fulfillment.

4.After-Sales & Storytelling

·Data-Driven Improvements: Analyze returns/fits to refine next collections.

·Brand Narrative: Leverage sustainability and performance benefits in marketing to eco- and comfort-focused consumers.

FAQ'S

1.Who makes the best quality men's jeans?

Top brands like Levi’s (heritage durability), Nudie Jeans (eco-friendly recycling), Iron Heart (heavyweight Japanese selvedge), and Outlier (tech-infused fabrics) excel in men’s denim by specializing in distinct quality aspects – prioritize material thickness (14-21oz), reinforced stitching, and brand repair programs for long-term value.

2.What are spandex jeans called?

Spandex-infused men’s jeans are commonly labeled as stretch jeans, flex jeans, or elastic denim (e.g., brands like American Eagle’s "Flex," Lee’s "Extreme Motion," or Wrangler’s "StretchX") – these blends (1-5% spandex/elastane) prioritize comfort, mobility, and shape retention for active lifestyles.

3.What type of jeans should a 60 year old man wear?

Opt for relaxed straight-fit or slim-straight jeans with elastic blends (1-3% spandex) from brands like Levi’s 541 Athletic Fit, Lee Comfort Series, or Wrangler Retro – these prioritize comfort, ease of movement, and a timeless silhouette while avoiding overly distressed or skinny styles for a polished, age-appropriate look.

4.What is the stretchiest material for jeans?

Jeans with 4-way stretch fabric (typically 2-4% elastane/spandex blended with cotton/polyester) like Lee Extreme Motion (5% elastane), American Eagle Ne(x)t Level Stretch, or Uniqlo Ultra Stretch offer maximum flexibility, adapting to movement in all directions while maintaining structure – ideal for active lifestyles or all-day comfort.

Conclusion

Bringing rayon and spandex into men's jeans isn't just a passing trend—it's a game-changer. These blends deliver that "just right" mix of stretch, shape retention, and next-level comfort, whether you're chasing festival crowds, powering through a workday, or just hanging out with friends. From heritage giants like Levi's and Wrangler to agile OEM/ODM partners such as DiZNEW, the options for performance denim are wider than ever.

If you're ready to elevate your brand with custom rayon/spandex jeans—complete with low MOQs, sustainable washes, and rigorous quality control—DiZNEW has you covered. Let’s co-create a denim line that keeps your customers moving, feeling great, and coming back for more. Contact us now to start your bespoke stretch-denim journey!