How to Verify CAD Pattern Makers for Custom Jeans in China?

You send a perfect tech pack to a new factory, but the sample that returns is a disaster. It's a frustrating setback that wastes your time, money, and faith in the process.

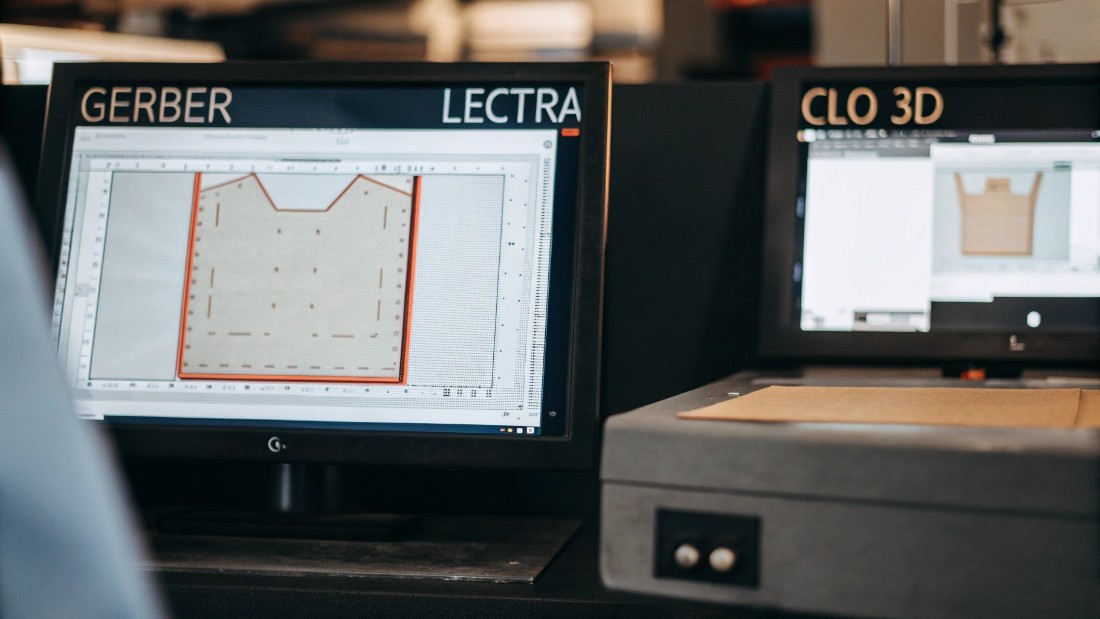

To verify a CAD pattern maker, you must evaluate their digital work, not just their resume. Request their actual pattern files, conduct a paid test project, and confirm their proficiency with modern software platforms like Gerber, Lectra, and CLO 3D.

Over my two decades running a denim factory, I've learned that the pattern maker is the architect of a garment. If the architect makes a mistake, the entire structure is flawed. That's why at my factory, DiZNEW, we consider our pattern team to be the heart of our technical operations.

A great pattern maker doesn't just trace lines; they translate a designer's creative vision into a technical blueprint that works in the real world. Here’s how you can make sure you have a true architect on your team.

What professional credentials and software skills should I look for in a CAD pattern maker?

You receive a resume listing "10 years of experience" and "Gerber proficiency." This tells you very little about the quality or complexity of their actual work, leaving you to guess their true skill level.

Focus on their portfolio of complex, export-quality denim over basic certifications. While skills in Gerber or Lectra are standard, their experience creating patterns for demanding Western brands is the most valuable credential.

When I hire a pattern maker, a software certificate is just a starting point. It's like a driver's license; it proves they know the basic controls, but it doesn't prove they can win a race. I want to see what they have built with those tools.

Have they worked on twisted-seam jeans for a German brand? Or a high-waisted, flared fit for a designer in New York? This specific, market-relevant experience is infinitely more valuable than a generic training certificate. It shows they understand the nuances of different body types, fit trends, and the high expectations of the international market.

The Difference Between a Technician and an Artisan

A truly great pattern maker combines technical skill with an artistic understanding of fabric and form.

| Skill Type | Basic Technician | Expert Artisan |

| Software | Knows the commands in Gerber/Lectra. | Uses software as an extension of their hand; fast and intuitive. |

Experience | Made simple trousers for the local market. | Has a portfolio of complex denim for EU/US brands. |

| Knowledge | Follows a tech pack literally. | Understands fabric shrinkage and wash effects; adjusts the pattern proactively. |

| 3D Skill | Has heard of 3D software. | Is proficient in CLO 3D or Browzwear for virtual prototyping. |

How can I request and evaluate samples or portfolios of their previous work?

A factory sends you beautiful photos of their finished products. But you have no way of knowing if their current team, or even the same pattern maker, was responsible for that work.

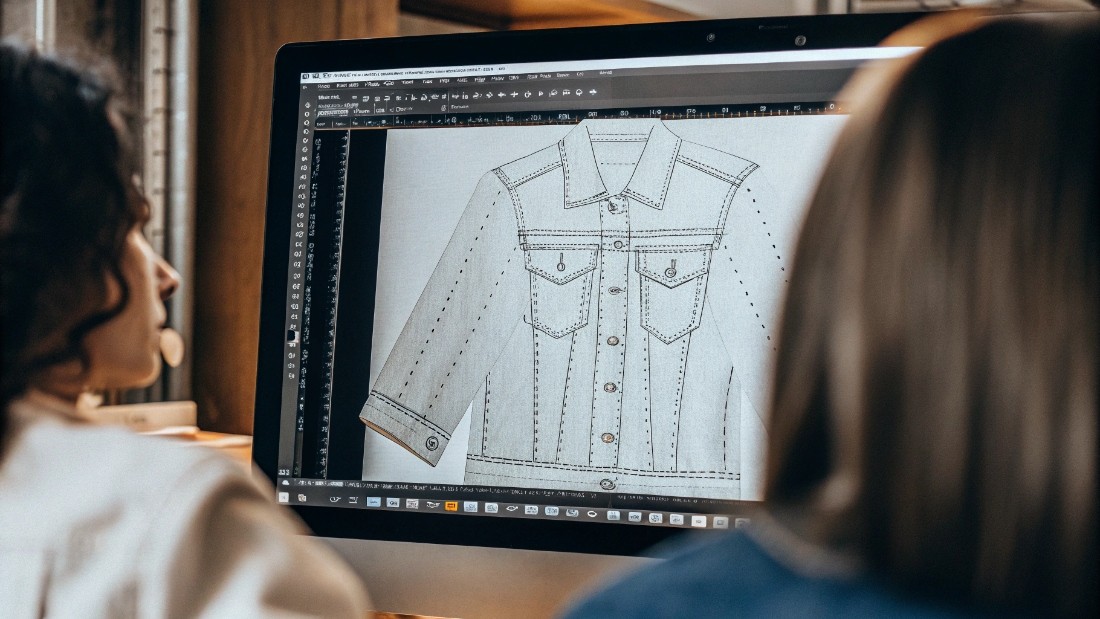

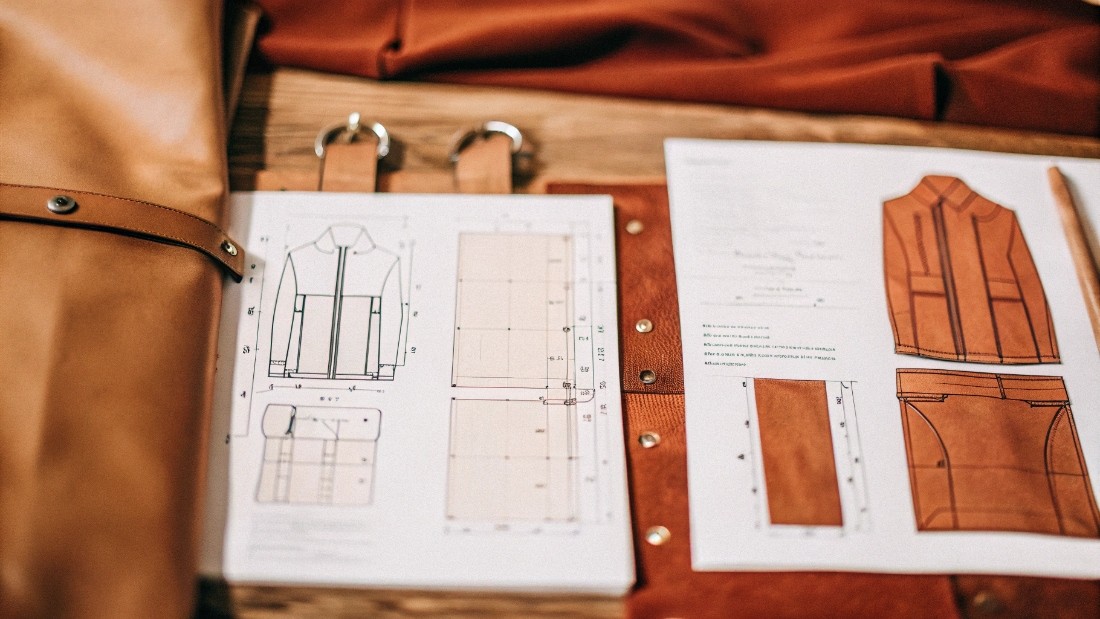

You must request the digital pattern files, not just photos. Ask for the native CAD files (like a .dxf or .zprj) of their most complex projects. This is the only way to evaluate their technical skill directly.

This is non-negotiable for me. A photo can be touched up, but a pattern file doesn't lie. When I evaluate a candidate, I ask to see the pattern for the most challenging garment they've ever made. I want to see the blueprint.

By opening the file, I can instantly assess the quality of their work. Are the curves smooth and economical? Are the notches logical? Is every piece clearly labeled? This digital file is the "handwriting" of the pattern maker, and it reveals their attention to detail, their logic, and their overall professionalism far better than any finished photo.

Reading the Blueprint

When you receive a pattern file, here is what you or your technical designer should look for.

Complexity is Key: Don't accept a simple 5-pocket jean as a sample. Ask to see the pattern for something with more challenging construction, such as a denim jacket, a pair of cargo pants with bellows pockets, or a jean with articulated knees. This demonstrates their ability to handle your more creative designs.

Signs of Professionalism: A professional pattern file is clean and easy to understand. Look for consistent labeling, precise placement of notches and drill holes, and logical organization of the pattern pieces. A messy, confusing file is a major red flag that suggests a disorganized workflow, which will inevitably cause problems in production.

Which practical tests best assess a CAD technician’s pattern-making proficiency?

You've seen their portfolio and it looks promising, but you're still hesitant. Committing your collection is a big step, and you need absolute confidence in their ability to execute your specific style.

The most effective method is a small, paid test project. Provide a tech pack for one of your own designs. This low-risk test allows you to evaluate their technical accuracy, communication, and problem-solving skills firsthand.

I use this method for every potential key partner. A test project moves beyond theory and into practice. I give them a tech pack for a style that has a few tricky details. Then, I watch their process. Do they review the file and come back with intelligent questions?

Or do they just start working without trying to understand the design intent? The questions they ask are often more telling than the first sample itself. It shows me if they are thinking critically and working to be a true partner, or if they are just a technician waiting for instructions.

Evaluating the Entire Process

The test isn't just about the final pattern; it's about seeing how they work and communicate.

Choose the Right Design: Select a style that is moderately complex. It should test their ability to interpret your sketches and measurements accurately. A design with a unique yoke, a special pocket shape, or a specific seam detail is a good choice.

Communication is Critical: A great pattern maker will communicate proactively. They will confirm key measurements, ask about your fit intention ("Do you want this to be snug or relaxed in the thigh?"), and flag any potential construction issues they see in the tech pack. Silence is a warning sign. It often means they are making assumptions that will lead to a bad sample.

What factory training standards and certification programs must my CAD team meet?

You find a pattern maker who is skilled today, but technology and fashion trends are always evolving. You need a partner whose factory invests in keeping their team's skills sharp and future-proof.

A world-class factory must enforce continuous education and training. Ask for proof of ongoing training in the latest software versions and, most importantly, in modern 3D design platforms like CLO 3D.

A factory's quality is a direct reflection of its investment in its people. At DiZNEW, training is not optional; it is a core part of our culture. My pattern team has weekly review sessions where we critique new samples together, sharing knowledge and solving problems as a group.

When software like CLO 3D became the new standard, we invested heavily in training our entire team. This commitment ensures we can handle the most innovative designs. Look for factories with quality management certifications like ISO 9001, as this indicates they have standardized processes for training and quality control.

Identifying a Forward-Thinking Partner

A factory's approach to technology and training tells you if they are a vendor for today or a partner for tomorrow.

The 3D Imperative: In today's market, proficiency in 3D virtual sampling is essential. A factory that has invested in training its pattern makers in CLO 3D or Browzwear can offer you faster development times, fewer physical samples, and a more collaborative design process. A factory that dismisses 3D is living in the past.

A Culture of Quality: Ask the factory manager how they develop their talent. Do they promote from within? Do they have senior pattern makers mentor junior ones? Do they invest in sending their team to technical seminars? A factory that is proud of its training program is a factory that is committed to excellence.

Conclusion

Verify a pattern maker by testing their practical skills on your product. Look beyond resumes to their digital portfolio and partner with a factory that proves its commitment to quality through continuous training.

Discover our Custom Gray-Blue and Mud Yellow Color Block Denim Jacket, offering OEM & ODM services for your unique designs.

OEM & ODM Custom Blue Irregular Patchwork Jeans for Wholesale: Unique designs tailored for your brand's vision.

Stacked skinny jeans with all-over rhinestone detail and vintage wash. Built for high-end and boutique fashion labels.

Eye-catching patchwork stacked jeans with contrast panels and utility pockets — bold choice for designer streetwear.