How to Source Clothing Samples from Manufacturers?

How to Start Sourcing Samples from Clothing Manufacturers?

Sample sourcing means ordering one-off or small-batch garments built exactly to your tech packs so you can check fit, fabric, and finish before committing to mass production. It saves time and money by catching issues early, ensures consistent quality, and proves a factory can meet your brand’s standards.

1. What exactly is “sample sourcing” and why is it essential for your apparel line?

Dive Deeper

1.Sample Sourcing vs. Garment Sourcing vs. Fashion Sourcing

·Sample Sourcing: One-off or tiny runs (often 1–30 pcs) matching your tech pack.

·Garment Sourcing: Broader process that includes selecting factories for full production, fabric, trims, and final assembly.

·Fashion Sourcing: Focuses on trend alignment, brand fit, and strategic partnerships in addition to production logistics.

2.Why Samples Are Non-Negotiable

·Risk Mitigation: Catch measurement drift, poor stitching, or color mismatches before you’re on the hook for thousands of units.

·Quality Assurance: Hands-on feel for fabric hand, stretch recovery, seam strength, and wash behavior.

·Communication Boost: A physical sample bridges gaps that even the clearest tech pack can’t close.

2. Which platforms and methods can you use to find a factory for your clothing line?

Dive Deeper

1.Online Marketplaces

·Alibaba: Huge network, MOQs typically 50–100 pcs, sample cost $30–$80, lead time 2–4 weeks.

·GlobalSources & Made-in-China: Similar scale; use filters for certifications (e.g., Oeko-Tex®).

·Sewport: Curated factories, lower MOQs (30–50 pcs), sample fees $40–$100.

2.Specialized Directories

·Maker's Row (USA): Focus on domestic partners, MOQs 10–30 pcs, sample cost $50–$120, turnaround 1–2 weeks.

·Kompass & Europages: European factories if you need near-shore options, MOQs 20–50 pcs.

3.Offline Channels

·Trade Shows: Texworld USA, Apparel Sourcing LA, Premiere Vision.

·Local Garment Districts: LA’s Fashion District or NYC’s Garment Center—walk factory floors and inspect setups firsthand.

4.Sourcing Agents & Consultants

·Agents handle vetting, auditing, and negotiations—ideal if you’re sourcing in Mandarin, Vietnamese, or Turkish markets.

·Typical agent fee: 5–10% of production value, but can save you 20–30% in missteps.

| Source Type | MOQ (Sample) | Lead Time | Cost per Sample (USD) |

Alibaba Factory | 50–100 pcs | 2–4 weeks | $30–$80 |

Sewport | 30–50 pcs | 3–5 weeks | $40–$100 |

| Maker’s Row (USA) | 10–30 pcs | 1–2 weeks | $50–$120 |

| Local Garment District | 5–20 pcs | 1 week | $60–$150 |

| Sourcing Agent (Asia) | 30 pcs | 3–5 weeks | $40–$100 |

3. What specifications, documents, and fabrics must you prepare before requesting a sample?

Dive Deeper

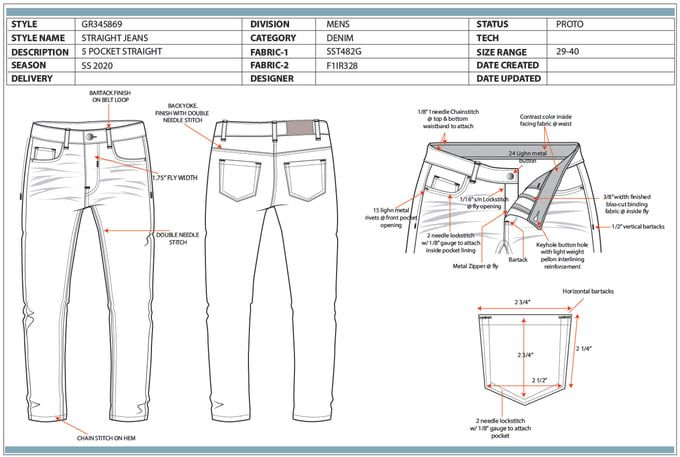

·Flat Sketches: Front, back, side views annotated with seam lines and stitch types.

·Measurement Chart: Graded specs for each size (e.g., waist, hip, inseam).

·Construction Notes: Stitch density (e.g., 10 SPI), seam allowance (e.g., 1 cm).

2.Bill of Materials (BOM)

·Fabric Details: Type (e.g., 12oz selvedge denim), GSM (grams per square meter), color lab dip codes.

·Trims & Notions: Rivets, buttons (with brand logo stenciling), labels, zipper specs.

·Packaging Notes: Poly bag size, hangtag design, sticker placement.

3.Fabric Sourcing Strategy

·Top Mills: Cone Denim (USA), Kurabo (Japan), Arvind (India).

·Swatch Requests: Always ask for at least 5×5" swatches in each shade.

·Sustainability Add-Ons: Oeko-Tex® certified, organic cotton blend, or water-saving wash processes.

| Document/Material | Purpose | Sample Example File |

Tech Pack | Guides factory on every detail | Tech_Pack_StyleA.pdf |

BOM | Lists all fabrics, trims, and codes | BOM_StyleA.xlsx |

Size Spec Chart | Provides graded measurements | Specs_StyleA.csv |

| Swatch Book | Physical fabric/color samples | Swatch_SetA/ |

| Sustainability Report | Certifies eco-friendly processes | Eco_Cert_2025.pdf |

4. How should you communicate design details and compliance requirements effectively?

Dive Deeper

1.Multichannel Communication

·Annotated PDFs: Use callouts (e.g., “Topstitching: 3mm from edge”).

·Mood Boards & Reference Photos: Drop images of your favorite industry pieces to illustrate aesthetic.

·Screen-Share Sessions: Walk factories through your tech pack live, draw markup in real time.

·Translation Glossaries: If factory speaks another language, supply key terms (e.g., “gusset,” “felled seam”).

2.Compliance & Sustainability Checks

·Chemical Safety: Provide lab tests for azo-free dyes or restricted phthalates—attach certificates.

·Social Audits: Share BSCI or Sedex audit reports. If none exist, consider funding a one-time audit to demonstrate commitment.

·Environmental Standards: Detail water-use goals (e.g., reduce wash water by 30%) and request factory process diagrams.

3.Critical-Thinking Perspective

·What if the factory pushes back on certification costs?

·Negotiate cost-sharing or phase audits over multiple styles.

·Consider a scaled timetable: audit one line per quarter, then expand.

5.What are the typical costs, lead times, and MOQs when starting sample requests?

Dive Deeper

1.Cost Breakdown

·Factory Sample Fee: $25–$80 (Asia), $50–$150 (USA).

·Shipping & Customs: $20–$50 international, $5–$15 domestic.

·Handling Fees: Agents often add 5–10% on top of factory quotations.

2.Lead Time Comparison

| Region | MOQ (Sample) | Lead Time | Total Cost Range (USD) |

China | 30 pcs | 3–5 weeks | $75–$130 |

| Vietnam | 50 pcs | 4–6 weeks | $60–$110 |

| USA (LA) | 5–20 pcs | 1–2 weeks | $80–$200 |

| Turkey | 20 pcs | 2–3 weeks | $70–$120 |

3.Insights from Reddit (r/SmallBusiness & r/EntrepreneurFashion)

·Negotiation Tips: Offer a forecast of future bulk orders to drive MOQ concessions.

·Hidden Costs: Some factories tack on pattern-making fees ($100–$200) or charge extra for graded sizes.

6. How do you evaluate the fit, quality, and workmanship of your received samples?

Dive Deeper

1.Fit & Comfort

·Model Fittings: Try on real bodies, not mannequins—note ease, ride, and proportion.

·Virtual Fitting Tools: Platforms like Browzwear let you simulate fit adjustments in software.

2.Wash & Wear Durability

·Home-Machine Test: Run samples through 10 wash cycles, note shrinkage percentage and color fade.

·Lab Tensile Test: Seam strength should exceed 15 kgf; record actual vs. target.

3.Workmanship Checks

·Stitch Count: Minimum 8–10 stitches per inch on high-stress seams.

·Hardware Inspection: Zippers should glide smoothly; rivets flush with fabric.

| Criterion | Target | Sample A Result | Pass/Fail |

Waist circ. drift | ±5 mm | +3 mm | Pass |

| Seam strength | >15 kgf | 14.5 kgf | Fail |

| Colorfastness | Grade 4–5 | Grade 4 | Pass |

| Shrinkage (after 10x wash) | ≤3% | 2.8% | Pass |

4.Critical Analysis

·If a sample fails, categorize the issue: fit vs. fabric vs. finish. Decide whether to revise the tech pack, change factory, or adjust materials.

7. Which negotiation strategies and next-step planning should you use before scaling up?

Dive Deeper

1.Negotiation Levers

·Tiered Pricing: Ask for 3%–5% off at 500–1,000 units, 7%–10% off at 1,500+ units.

·Payment Terms: Propose 30/70 (30% deposit, 70% on completion) or net-30 on shipment.

·Bundled Styles: Offer to group multiple SKUs to reduce per-style MOQ.

2.Sustainability Clauses

·Shared Savings: If the factory cuts water usage by 20% in washing, split those cost savings.

·Green Audit Roadmap: Phase in factory upgrades—wastewater treatment, solar power—over 12–18 months.

3.Pilot Run & Quality Gates

·Pilot Order: 50–100 pcs under final specs.

·Inspection: Third-party QC checks (IQC/AQL) before shipping pilot.

·Sign-Off: Use pilot results to lock in contract terms for the full run.

4.12-Month Capacity Forecast

| Month | Estimated Units | Lead Time Buffer | Payment Scheduled |

| June | 1,000 | +2 weeks | 30% deposit |

| July | 1,500 | +3 weeks | 70% deposit |

| Aug–Sept | 2,000 | +4 weeks | Net-30 terms |

1.How much is a sample from a clothing manufacturer?

Clothing sample costs typically range from50−500+ depending on fabric quality, design complexity, and order quantity, with most manufacturers offering bulk-order discounts and sample fee rebates upon production commitment.

2.How do i partner with a clothing manufacturer?

To successfully partner with clothing manufacturers, prioritize verifying their MOQs (minimum order quantities), production capabilities, and compliance certifications, while leveraging sourcing platforms like Alibaba or Fashionesta to negotiate exclusive contracts and request factory audit videos for quality assurance.

3.How to source fabric for a clothing line?

To source fabric for your clothing line efficiently, utilize wholesale platforms like Alibaba or Texpedia to compare sustainable textiles and request digital swatches, verify OEKO-TEX® certifications for safety compliance, and attend textile trade shows like Première Vision to negotiate bulk discounts while evaluating minimum order quantities (typically 100-500 yards per design).

4.How do i start a new clothing collection?

Launch a successful clothing collection by first conducting trend analysis via tools like WGSN or Trendalytics, then create tech packs with 3D design software (e.g., CLO3D), partner with ethical manufacturers through platforms like Maker's Row, and validate designs through pre-sales campaigns or pop-up events before full production – typically requiring 5k−20k initial investment for sampling, MOQs, and sustainable fabric sourcing.

Conclusion

Navigating the sample-sourcing journey might feel overwhelming at first, but by breaking it down—defining your needs, finding the right factory, preparing a rock-solid tech pack, communicating clearly, and rigorously evaluating your prototypes—you turn uncertainty into confidence. Every data point you track, from sample costs and lead times to fit scores and wash results, sharpens your decision-making and protects your brand’s reputation.

Remember, the sample stage isn't a hurdle—it's your secret weapon for quality control, cost savings, and creative innovation. With DiZNEW's end-to-end OEM/ODM expertise, agile low-MOQ production, and sustainability-driven processes, you'll move from concept to wardrobe staple faster and smarter.

Ready to bring your denim vision to life? Reach out to DiZNEW today for your custom sample quote, and let’s make your next collection truly standout.