How Much Investment Is Required for Jeans Pant Making?

In today’s fashion landscape, jeans aren’t just a wardrobe staple—they’re a statement of style, identity, and sustainability. Yet, behind every perfectly faded pair lies a complex web of costs: raw materials, labor, finishing processes, and compliance with environmental standards. For aspiring denim entrepreneurs, the burning question is simple: How much capital do you really need to launch and scale a jeans line?

Starting a jeans production venture typically requires an initial investment ranging from USD 15,000 to USD 50,000 for small runs (30–200 pieces), covering fabric, trims, sampling, and basic finishing. Scaling to larger orders (1,000–10,000 pieces) can push upfront costs to USD 100,000+ but yields lower unit costs through economies of scale. Precise figures depend on fabric quality, customization complexity, and chosen manufacturing model (OEM/ODM vs. in-house).

Imagine a boutique designer in Los Angeles who invested just USD 18,000 to launch 50 customized selvedge jeans. By negotiating favorable MOQ terms with a seasoned Chinese OEM like DiZNEW, she transformed that initial outlay into a 10,000-unit contract within six months—and built a cult following. Ready to explore the numbers behind your own denim success?

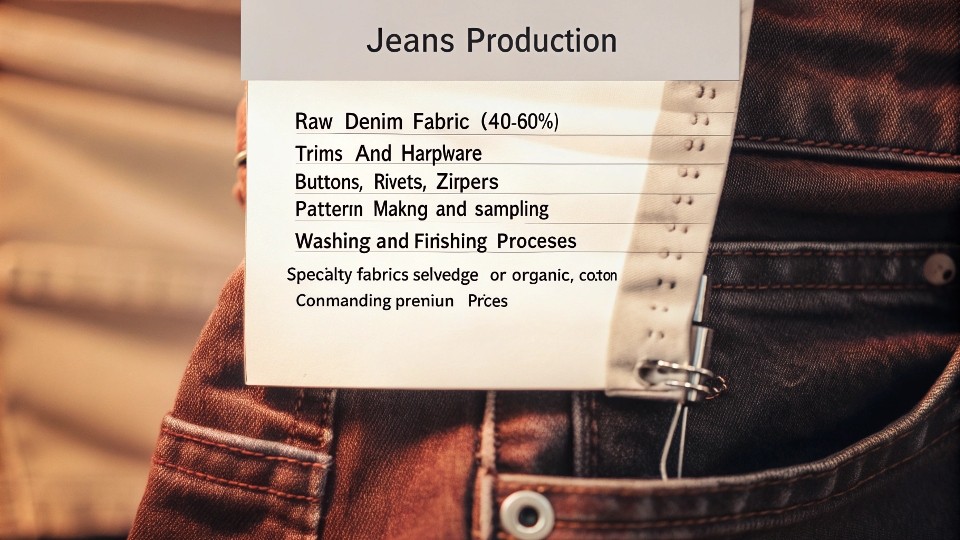

What Are the Key Cost Components in Jeans Production?

Key cost drivers in jeans production include raw denim fabric (40–60% of total), trims and hardware (buttons, rivets, zippers), pattern making and sampling, washing and finishing processes, and quality control. Specialty fabrics like selvedge or organic cotton command premium prices, while intricate wash treatments (e.g., laser, stone wash) add both labor and equipment expenses. Understanding each component's share is crucial for accurate budgeting.

Raw Denim Fabric

Conventional vs. Premium: Standard 12oz cotton denim can cost USD 4–6 per yard. Premium selvedge or organic variants range from USD 8–15 per yard. For a single pair requiring roughly 1.5–2 yards, fabric alone can drive USD 6–30 per unit.

Mill Relationships: Long-term commitments with mills yield volume discounts—DiZNEW’s 20 years of partnerships unlocks favorable tiered pricing at large volumes.

Trims and Hardware

Metal vs. Eco-Plastic Buttons: Traditional copper buttons cost USD 0.10–0.30 each; eco-friendly biodegradable alternatives may cost USD 0.40–0.60.

Rivets and Zippers: Branded zippers (YKK) command USD 1.00–2.00 per unit, while generic options run USD 0.50–1.00.

Labeling & Packaging: Custom woven labels (USD 0.20–0.40), hangtags (USD 0.10–0.30), and polybag packaging (USD 0.05–0.15) add incremental costs.

Pattern Making, Sampling, and Prototyping

Initial CAD Patterns: USD 100–300 per design.

Physical Samples: Each prototype can cost USD 50–150 depending on wash treatment. Multiple iterations often required for perfect fit.

Washing, Finishing, and Quality Control

Water Usage & Costs: A single wash cycle can consume 20–50 liters of water; wastewater treatment fees add USD 0.02–0.05 per liter.

Special Effects: Laser distressing, hand-sanding, or ozone treatments carry labor and equipment lease fees that can add USD 3–10 per pair.

Inspection & QC: Third-party audits or in-house inspectors typically cost USD 0.50–2.00 per unit.

Overhead & Compliance

Factory Overheads: Utilities, equipment depreciation, and staff salaries can add 10–20% overhead to per-unit cost.

Environmental Compliance: Certifications for organic or sustainable production (e.g., GOTS, OEKO-TEX) may require annual fees of USD 1,000–5,000.

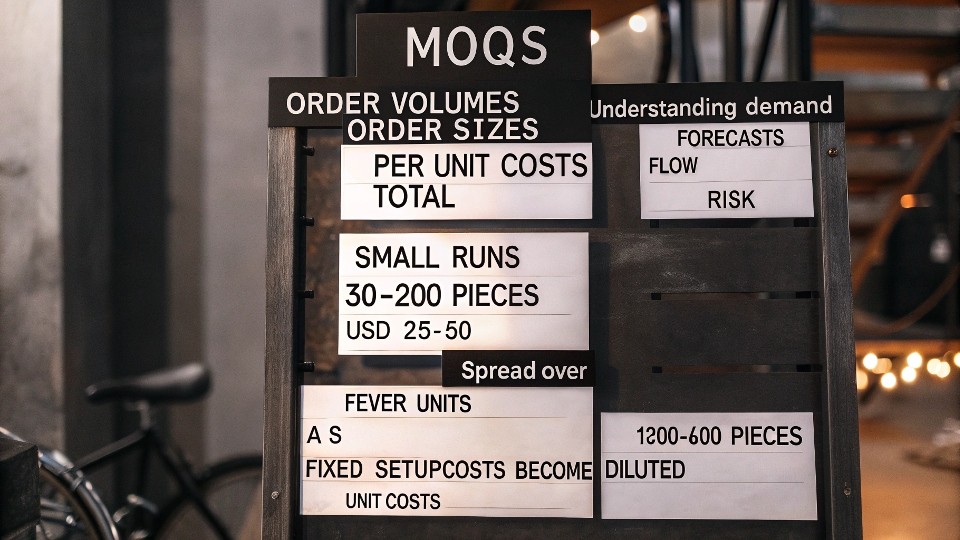

How Do Order Volume and MOQ Impact Your Initial Outlay?

Minimum order quantities (MOQs) and order size directly affect per-unit costs and total investment. Small runs (30–200 pcs) have higher unit costs—often USD 25–50—due to setup fees spread over fewer units. As order volume increases to 1,000–10,000 pieces, fixed setup costs dilute, driving down unit cost to USD 8–20. Understanding your demand forecast, cash flow, and inventory risk is essential when negotiating MOQs with factories like DiZNEW.

MOQ Structures at DiZNEW

Low MOQ (30 pcs): Ideal for designers testing new styles. Setup fees (USD 200–500) are spread across fewer pairs, resulting in higher per-unit costs.

Mid-Scale Runs (200–1,000 pcs): Setup costs become more manageable; volume discounts on fabric and trims start to apply.

Mass Production (5,000–10,000+ pcs): Peak economies of scale. Factories can dedicate entire production lines, unlocking best-in-class pricing on raw materials.

Fixed vs. Variable Costs

Fixed Costs: Pattern fees, mold creation, setup labor—constant regardless of quantity.

Variable Costs: Fabric, trims, per-piece labor—scale with volume.

Break-even Analysis: Calculating at which volume your per-unit cost dips below your target retail margin.

Cash Flow & Inventory Management

Prepayment Requirements: Many factories require 30–50% deposit up front.

Lead Times: Longer lead times for large orders (60–90 days) vs. small runs (30–45 days).

Inventory Holding Costs: Warehousing can cost USD 0.50–1.00 per unit per month. Overproduction risk must be balanced against potential stockouts.

Risk Mitigation Strategies

Staggered Production: Splitting a large order into two batches reduces upfront capital and allows mid-run adjustments.

Collaborative Forecasting: Shared sales data with the factory can adjust MOQs and prevent overstock.

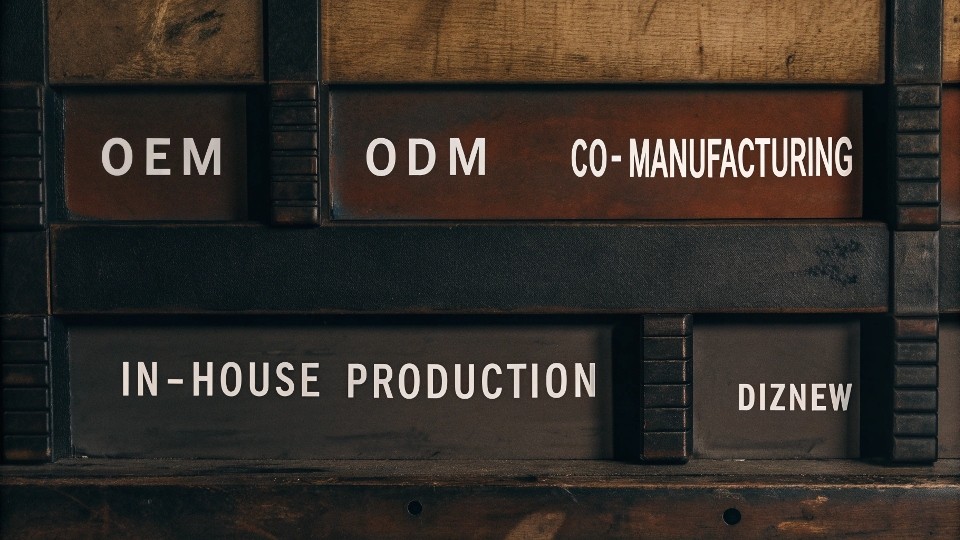

Which Manufacturing Models Can Reduce Upfront Investment?

Choosing the right manufacturing model—OEM, ODM, co-manufacturing, or in-house—determines capital requirements and risk. OEM/ODM partnerships allow you to leverage factory infrastructure with low initial CapEx, while co-manufacturing or small-batch runs provide flexibility at slightly higher per-unit costs. In-house production demands heavy investment in machinery, staff, and compliance. For most startups and boutique brands, partnering with DiZNEW as an experienced OEM/ODM ensures deep customization, minimal CapEx, and access to premium supply chains.

OEM vs. ODM: Definitions & Trade-Offs

OEM (Original Equipment Manufacturer): You supply designs and specs; factory sources materials and produces to your tech pack. Pros: Full design control, flexible MOQ. Cons: You manage branding, packaging, and quality oversight.

ODM (Original Design Manufacturer): Factory offers ready-to-manufacture designs you can co-brand. Pros: Lower design costs, faster time-to-market. Cons: Less unique product differentiation.

Co-Manufacturing & Small-Batch Runs

Shared Production Lines: Multiple brands share line setups and run times, reducing individual costs.

Maker Spaces & Microfactories: Ideal for hyper-local, artisanal denim labels, but often limited to specialized washes.

In-House Manufacturing

CapEx Investments: Denim looms (USD 100,000 each), sewing machines (USD 3,000–10,000), washhouse equipment (USD 50,000–200,000).

Ongoing Overheads: Staff salaries, utilities, maintenance—can exceed USD 100,000 annually.

Regulatory Compliance: Environmental permits for water discharge and chemical usage add complexity.

Why DiZNEW’s Model Works for You

Turnkey Solutions: From prototyping to bulk production, warehousing, and shipping.

Deep Customization: Plus sizes, baggy, skinny, stacked, jogger—over 20 years of pattern archives.

Risk Reduction: Low MOQs, staggered payment terms, dedicated account managers.

What Hidden and Ongoing Costs Should You Anticipate?

Beyond raw materials and production, brands must budget for design revisions, sampling iterations, shipping/duties, warehousing, marketing, and labeling. Unexpected costs can include compliance audits, customs delays, and currency fluctuations. Planning for 10–20% additional buffer on top of projected per-unit costs safeguards against budget overruns and ensures smooth operations.

Design Revisions & Sampling

Iteration Cycles: Each round of sample tweaks costs USD 50–150. Brands typically iterate 2–4 times before sign-off.

Tech Pack Updates: Adjusting measurement specs or construction details may incur CAD rework fees (USD 50–100).

Logistics: Shipping, Duties, and Customs

Freight Costs: Air freight (USD 6–10 per kg) vs. sea freight (USD 1,500–2,500 per 20ft container).

Import Duties: Jeans tariffs vary by country—USA at 10–20%, EU at 12–20%.

Customs Brokerage Fees: USD 50–150 per shipment.

Warehousing & Distribution

Local Warehousing: USD 0.50–1.00 per unit per month.

Fulfillment Services: Pick-and-pack fees of USD 1.00–2.00 per order.

Marketing, Branding, and Packaging

Photography & Lifestyle Shoots: USD 1,000–5,000 per campaign.

Digital Marketing: Paid ads can run USD 0.50–2.00 per click.

Custom Packaging: Branded boxes or bags add USD 0.50–1.50 per unit.

Quality Assurance & Compliance

Random Inspections: Third-party QC costs USD 150–300 per site visit.

Sustainability Audits: Certifications (e.g., Bluesign, Fair Trade) can cost USD 2,000–10,000 annually.

How Can You Secure Funding and Mitigate Financial Risk?

Funding options for jeans startups include pre-sales, crowdfunding, wholesale partnerships, trade financing, and government grants. Negotiating extended payment terms (30/30/40) with factories and leveraging export credit agencies can ease cash flow. A 20% contingency buffer on your project budget helps cover unforeseen expenses and protects profit margins.

Pre-Sales & Crowdfunding

Platforms: Kickstarter, Indiegogo campaigns can raise USD 20,000–100,000.

Incentives: Early-bird pricing, limited-edition washes, custom patches drive backer excitement.

Wholesale & Retail Partnerships

Net Payment Terms: Retailers may offer 30–90 days to pay for inventory.

Consignment vs. Purchase Order: Consignment reduces risk but ties up display space.

Trade Finance & Export Credits

Letter of Credit (LC): Bank-backed guarantee reduces factory risk and may improve payment terms.

Export-Import Bank Programs: Low-interest loans for U.S. buyers importing from China.

Government Grants & Subsidies

Fashion Incubators: Regional grants (USD 5,000–20,000) for sustainable or tech-driven apparel.

Tax Incentives: R&D tax credits in the U.S. and Europe for design innovation.

Factory Payment Negotiations

Milestone Payments: 30% deposit, 30% pre-production, 40% before shipment.

Volume Rebates: Agree in advance on discounts if annual volume exceeds thresholds.

Estimating your jeans production investment requires a granular look at raw materials, manufacturing models, order volumes, and hidden overheads. By partnering with DiZNEW—China’s 20-year veteran in denim OEM/ODM—you gain access to low MOQs, deep customization, and turnkey support from prototyping to global logistics. Ready to turn your denim dream into a profitable reality? Contact DiZNEW today for a tailored quote on your next jeans pant line. Let’s build your brand together, one pair of perfectly crafted jeans at a time.

Washed denim cargo jeans with raw edge detail and oversized pockets for a bold streetwear look.

Vintage washed oversized jeans with bold embroidered patches, ideal for custom streetwear and bulk orders. Stylish and durable.

Custom Blue denim shorts with crystal detailing, blending luxury and street style. Stand out with this personalized denim design.

Discover premium DiZNEW denim jeans with decorative studs for a sparkling, stylish look. Order today!