Denim Evolution: 1940s vs 2020s Trends & Changes

How do denim clothing now differ from 80-odd years ago?

Modern denim differs from vintage workwear through advanced stretch blends, eco-friendly dye methods, precision laser finishes, and a vast style spectrum—from slim streetwear to high-fashion collaborations—whereas 80 years ago denim was rigid, utilitarian, and mass-produced with little customization or environmental care.

1.What is denim and how long has it been around?

Snippet: Denim started as sturdy “serge de Nîmes” in 17th-century France, became the iconic riveted blue jeans in 1873, and by the 1950s had morphed into a global fashion staple—evolving from workwear to a must-have style item.

Dive Deeper

1.Origins & Milestones

·1600s – Nîmes, France: Craftsmen wove a durable twill called “serge de Nîmes.”

·1700s – England: “Jeane” cloth emerges for sailors; coarser but similar weave.

·1873 – California: Levi Strauss & Jacob Davis patent copper-riveted waist overalls.

·1930s – Industrial: Indigo rope-dyeing standardizes deep blue hues.

·1950s – Pop Culture: Icons like James Dean turn jeans into a teenage rebellion symbol.

| Year | Event |

1675 | “Serge de Nîmes” first woven |

1873 | First riveted blue jeans patented |

1900 | Mass manufacturing of denim jumpsuits and overalls |

1930 | Rope-dye technique becomes industry standard |

| 1955 | Marlon Brando wears jeans in “Rebel Without a Cause” |

| 1980s | Stone-washing and acid-wash trends explode |

| 2020s | Rise of sustainable, stretch, and digital-print denim |

2.How was denim produced in the early 1940s compared to today?

Snippet: 1940s denim was 100% cotton, shuttle-loom woven, rope-dyed, and stone-washed by hand. Today’s denim is made on high-speed looms, blended with stretch fibers, enzyme-washed, laser-etched, and ozone-bleached.

Dive Deeper

1.Vintage Production

·Weaving: Slow shuttle looms created that neat selvedge edge but only made ~10 meters per hour.

·Dyeing: Rope indigo vats dipped denim dozens of times for depth.

·Finishing: Pumice stones tumbled with jeans over days; each pair got a handcrafted fade.

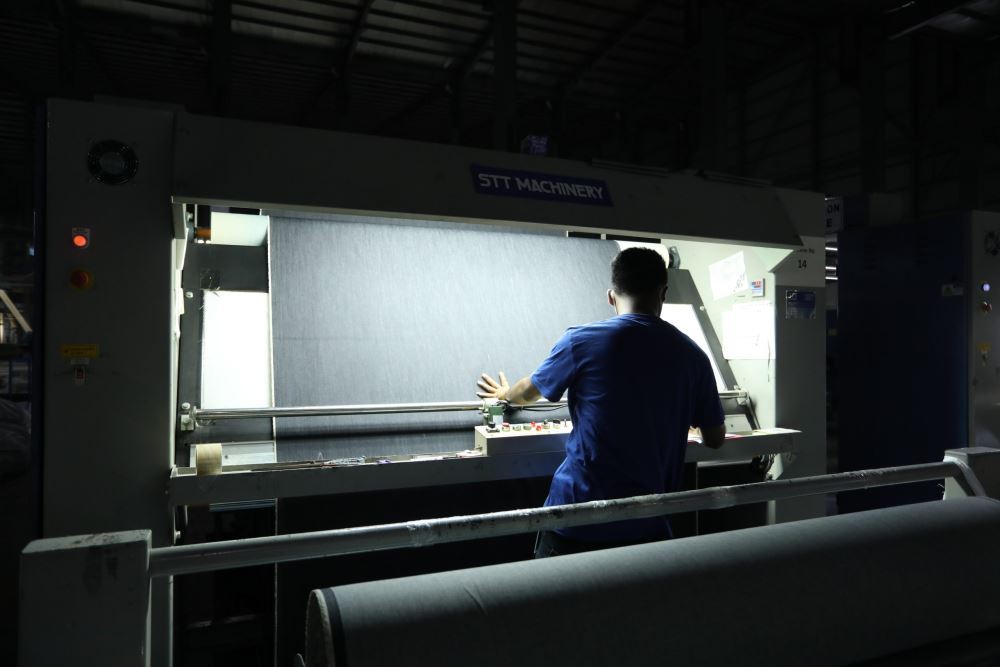

2.Modern Production

·Loom Speed: Projectile looms crank out 500+ meters per hour.

·Fabric Blends:

·Cotton: 88–98%

·Elastane: 2–12% for stretch

·Recycled Fibers: Up to 10% polyester/Tencel mixes

·Automated Finishes:

| Finish Type | Old Method | New Method | Water Use Reduction |

Fading | Pumice stones (2–3 days) | Enzyme wash (4–6 hours) | 40–60% less |

| Bleaching | Acid baths (toxic runoff) | Ozone treatment (no water) | 100% less |

| Patterns | Hand sanding & scraping | Laser etching (minutes per garment) | N/A |

| Dyeing | Multi-dip rope vats | Foam dyeing (one-pass system) | 90% less |

3.Critical Perspective

·Speed vs. Craft: Faster isn’t always better—many niche brands still hand-finish to maintain that “one-of-a-kind” character.

·Sustainability vs. Energy Use: Cutting water is great, but lasers and ozone machines gulp electricity—so the eco-win isn’t always clear-cut.

3.How have denim fabrics and materials evolved over the past 80 years?

Snippet: Denim went from a raw cotton twill you tailored yourself to a luxury “final good,” arriving stretch-ready, pre-washed, and branded, often with recycled fibers or specialty blends.

Dive Deeper

1.Material Shifts

| Era | Cotton (%) | Elastane (%) | Specialty Fibers | Notes |

1940s | 100 | 0 | None | Heavy, rigid, zero stretch |

| 1980s | 98 | 2 | Small polyester mixes | First stretch jerseys |

| 2000s | 95 | 5 | Tencel, Modal | Comfort denim boom |

| 2020s | 85–95 | 1–5 | Hemp, recycled PET | Eco-focused, technical fabrics |

2.Is Denim a Final Good?

·Then: Mills sold unfinished denim bolts; local tailors made garments.

·Now: Brands sell fully finished, garment-dyed jeans directly to consumers—so denim itself can be the “final good.”

3.Critical Perspective

·Comfort vs. Longevity: More stretch equals better fit but can reduce fabric life if over-blended.

·Eco Marketing: Many brands tout “recycled” or “organic,” but the full dyeing/finishing process still uses chemicals and water—watch out for greenwashing.

4.Which manufacturing technologies distinguish modern denim from vintage methods?

Snippet: Modern denim uses enzyme washes, ozone bleaching, laser etching, and digital printing to achieve complex finishes in hours rather than days, replacing labor-intensive pumice stone and acid treatments.

Dive Deeper

1.Tech-Driven Finishes

·Enzyme Wash: Cuts back abrasions and water usage by up to 50%.

·Ozone Bleaching: Zero-water option that “bleaches” indigo in under an hour.

·Laser Etching: Programmable fade patterns, logos, and whiskers—no manual sanding.

·Digital Printing: High-res prints (camouflage, florals, tie-dye) directly onto denim.

2.Workflow Comparison

| Step | Vintage | Modern |

Fade Creation | Pumice + manual rubbing (2–3d) | Enzyme bath (4h) + laser accents |

| Whisker Lines | Hand-sanded with stones | Laser-etched in batch (minutes/pair) |

| Color Setting | Resin coating by hand | Automated polymer finish in tunnel |

| Decoration | Hand embroidery & patches | CNC embroidery & digital heat transfers |

5.What differences in fit and style mark denim fashions from the 1940s, through the 1980s, to today?

Snippet: 1940s denim was boxy utility; the 1980s brought high-waist acid wash and baggy silhouettes; now you’ve got skinny, straight, wide-leg, cropped, and even “mom jeans” with tailored stretch for every body and vibe.

Dive Deeper

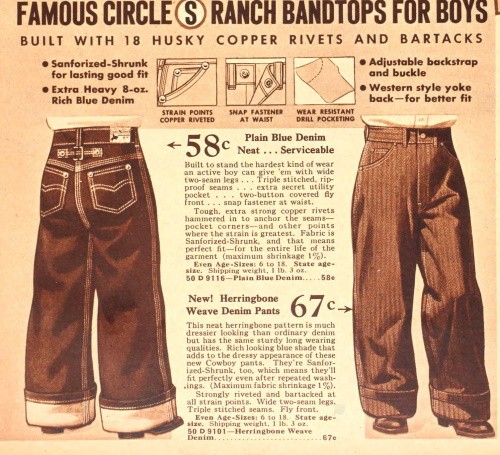

1.1940s Utility Cuts

·Silhouette: High waist, straight leg, roomy hip—designed for work freedom.

·Typical Pair: Canvas-reinforced pockets, heavy hardware, lived-in patina.

2.1980s Style Explosion

·Acid-Wash Craze: Bold, bleached patterns with high contrast.

·Baggy & High-Rise: Oversized fits in neon and pastel hues.

3.Modern Fit Diversity

| Fit Type | Elastane (%) | Vibe |

Skinny | 8–12 | Streetwear, clubbing |

Slim | 3–5 | Smart casual, office |

Straight | 1–3 | Everyday wear |

| Relaxed | 0–1 | Workwear homa |

| Wide-Leg/Mom | 0–5 | Y2K revival, comfort focus |

| Cropped | 2–6 | Trendy, layering piece |

6.How is denim fashion related to our lifestyle and cultural associations?

Snippet: Originally workwear for miners and railroaders, denim now slays in streetwear, festivals, and high fashion. From TikTok DIY rips to luxury collabs (think Balenciaga x Levi’s), denim reflects personal stories and online community trends.

1.From Workwear to Runway

·1900s: Denim = durability for blue-collar America.

·1950s–70s: Hollywood rebels make jeans a symbol of freedom.

·2000s: Streetwear brands and designer labels transform jeans into status symbols.

2.Lifestyle Scenes

·Streetwear & Sneakerheads: Distressed jeans, custom patches, and artist collabs.

·Outdoor Enthusiasts: Reinforced seams, water-repellent finishes for hiking.

·Event Wear: Glitter coatings, rhinestones, and sequins for concerts and parties.

3.Reddit’s Take: “Denim Identity”

·Raw vs. Washed: Purists debate whether raw denim’s break-in is “worth the pain.”

·Selvedge vs. Stretch: Communities dissect grain, edge detail, and comfort vs. craft.

7.Are sustainable practices in denim manufacturing different now compared to 80 years ago?

Snippet: Unlike the water-heavy stone and acid washes of the past, today’s sustainable mills use foam dyeing, waterless ozone, recycled fibers, and solar power—slashing water by up to 90% and cutting CO₂ emissions by nearly 30%.

Dive Deeper

1.Old-School Environmental Toll

·Stone & Acid Washes: 50–80 L of water per pair; toxic sludge in rivers.

·Indigo Dyeing: Multiple dips; large vats of chemical runoff.

2.Modern Eco Innovations

Innovation | Description | Impact |

Foam Dyeing | Dye foam applied directly to yarn | 90% less water |

| Ozone Bleaching | Ozone gas replaces bleach baths | 100% less water, fast cycle |

| Recycled Fibers | PET bottles → polyester blended with cotton | Cuts landfill waste |

| Solar-Powered Mills | Solar arrays power finishing lines | 30% less grid electricity |

3.DiZNEW Case Study

·Water Use: From 60 L to 6 L per jean via Cool Transfer.

·Energy Mix: 35% solar, 65% grid; aiming for 50/50 in 2026.

·Carbon Footprint: Reduced by 28% through efficient finishes and local sourcing.

1.How did jeans change over time?

From durable 19th-century workwear to modern sustainable fashion statements, jeans evolved through cultural shifts (1950s rebellion, 1980s designer denim), adapting with stretch fabrics, eco-dye tech, and inclusive sizing to reflect social values while maintaining their iconic status as global wardrobe staples.

2.Why is vintage denim better?

Vintage denim is prized for its superior craftsmanship, durable heavyweight cotton, and unique fading patterns shaped by decades of wear, offering eco-conscious shoppers a sustainable alternative to modern fast fashion while embodying timeless style and unmatched break-in comfort that mirrors its history.

3.What were the trends in the 80s denim?

1980s denim trends featured bold acid wash finishes, high-rise mom jeans, and oversized silhouettes popularized by pop icons, with stonewashing techniques and ripped detailing dominating youth culture, while designer brands like Calvin Klein pioneered logo-embellished waistbands – a retro aesthetic now revived in sustainable vintage remakes and Y2K-inspired streetwear.

4.Why is denim differents?

Denim differs due to weaving techniques (like selvedge vs. modern looms), indigo dyeing methods, and fabric weights (8-21oz), shaped by regional traditions (Japanese craftsmanship, American workwear) and modern innovations like stretch blends and eco-friendly dyes, creating distinct textures, durability, and fade patterns prized by denim enthusiasts and sustainable shoppers alike.

Conclusion

Denim’s journey from rugged 1940s workwear to today’s high-tech, lifestyle staple proves its enduring charm and chameleon-like adaptability. Whether you’re after raw selvedge jeans, stretchy skinny fits, eco-friendly washes, or fully custom prints, DiZNEW’s OEM/ODM services—from 30-piece minimums to bulk orders—have you covered.

Ready to make your own denim statement? Hit up DiZNEW for a free quote and design chat—let’s bring your next denim collection to life!